The craft beer industry has been booming, with many small breweries and craft brewers emerging around the world. Brewery equipment consists of various components required in the brewing process. These include tanks, kettles, filters, pipes, and other instruments required for brewing. When purchasing the main equipment for a brewery, there are several factors to consider. The selection and application of brewing equipment directly determines the quality and production efficiency of the beer.

Basic Steps in the Beer Brewing Process

- Mashing: The first step in brewing beer is mashing. This process involves mixing malt with hot water to convert starches into fermentable sugars. Mashing usually takes an hour, and the temperature must be carefully maintained for optimal sugar conversion.

- Separation: After the mashing process is complete, the resulting liquid, called wort, is separated from the spent grains through a filtering process. This process ensures that all the fermentable sugars are extracted from the grains.

- Boiling: The next step in brewing beer is boiling. During this process, hops are added to the wort to provide flavor and bitterness. The boiling process lasts about an hour and also helps to purify the wort.

- Fermentation: After the wort is cooled, it is transferred to a fermenter, yeast is added, and the fermentation process begins. The yeast consumes the sugars in the wort, producing alcohol and carbon dioxide as byproducts. The fermenter’s temperature is critical at this stage because it affects the taste and aroma of the finished beer. Once fermentation is complete, just add a small amount of sugar to some bottles or kegs before transferring the beer. The remaining yeast consumes the sugars, produces carbon dioxide, and forms natural carbonation in the beer.

Basic ingredients for beer brewing

- Water: Water is the most abundant ingredient used by brewers. It is an integral part of the brewing process and the best quality water should be used. Some regions are known for their unique beers due to the mineral content in their water. Despite this, many brewers use carbon dioxide filtration to produce the best product. Brewers will use special regulators to increase the flavor of the water.

- Yeast: There are more than 1,500 yeasts that can be used to brew different styles of beer, including lager yeast, ale yeast, and other yeast strains. Brewers add yeast to beer to convert fermentable sugars into alcohol. A single yeast strain can be used over and over again to brew countless bottles of beer.

- Malted barley: Malt is the main ingredient that determines the flavor of beer. Malt is the source of starch in beer. Traditionally, brewers use malted grains or malted barley. Malted grains or barley are roasted to varying degrees to give the beer a variety of colors from golden to dark amber. Depending on the specific beer style, other grains can be used in the malting process.

- Hops: Provide flavor and aroma to beer, and they are also crucial for preservation when brewing beer. Since malt provides sweetness, hops balance the flavor of beer. Hops are usually the only preservative added during the brewing process, and they impart different flavors, including citrus and floral notes.

Brewery Equipment Used in the Brewing Process

Choosing a Heat Source

- Steam: Steam-heated vessels are fairly common and require a steam generator. This simply converts tap water into boiling steam which is then piped into a steam jacket mounted on the vessel. Steam generators are usually powered by gas, electricity, or diesel.

- Electricity: Electrically heated vessels usually use elements similar to those found in a regular kitchen kettle. These elements come in a variety of sizes and powers, and the best have 2 or 3 elements that can be turned off and on, allowing a degree of control over the heating. The elements in an electric brewery are built-in and require no additional equipment.

Mashing Tun

Wort tuns come in many types, from the simplest open vessels to closed heated vessels complete with stirring paddles. The more features, the higher the cost. For larger production volumes (above 200 liters or so), manually mixing the wort can become difficult. If you plan on using a step wort, you will need a wort tun that can be heated.

Lauter Tun

The lauter tun is equipped with a filter to separate the sweet wort from the grain. It is also equipped with a flushing ring and is connected to the HLT via a flow meter. The ability to recirculate hot wort back onto the grain is very useful for clarifying the wort before transferring it to the boil kettle. The lauter tun does not usually need to be heated. During the rinse process, the filtered hot wort will be pumped to the boil kettle.

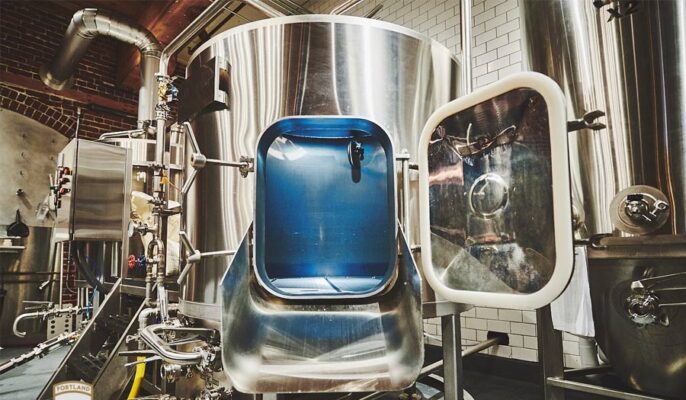

Fermentation Tanks

The type of fermentation vessel depends largely on the type of beer you want to brew. From simple open vessels to pressurized single tanks, there are several aspects to consider. Many small breweries prefer closed pressurized vessels. Fermentation vessels can be customized in a variety of ways. Some common modifications include dry hopping ports, carbonation stones, stirring arms, and agitation valves. As standard, they should usually be equipped with temperature probes, spray balls for CIP, and sampling valves.

CIP Cleaning

CIP (cleaning in place), is a practical addition to a brewery. Most small breweries have CIP systems in their cellars and brewery vessels, a simple spray ball that sprays the cleaning solution at high pressure, covering the inside.

Filling Machines

Whether you use cans or bottles, you will need a filling machine. There are many types of filling machines to choose from. For bottlers in particular, you need to know if you want to package carbonated beer or rely on bottle conditioning for carbonation. Filling lines vary in how many filling heads you need, but can also perform many other tasks, from washing to labeling and capping.

How to choose beer brewing equipment?

Production scale

First, you need to clarify your production scale, including current production and future expansion plans. Equipment of different scales is suitable for different production needs, such as micro-brewing equipment suitable for home brewing or personal enthusiasts, small brewing equipment suitable for small bars, restaurants, etc., and medium and large brewing equipment suitable for places with large production.

Equipment quality and material

Choosing high-quality brewing equipment can ensure the quality of brewed beer, and the life of the equipment will be longer, reducing the cost of later maintenance. Pay attention to the manufacturing process, durability, and market reputation of the equipment. Stainless steel is the preferred material for making beer brewing equipment because it has the advantages of corrosion resistance, easy cleaning, and high-temperature resistance.

Convenient operation

Choose equipment that is easy to operate and maintain to reduce labor costs and operating difficulty. The operating interface of the equipment should be intuitive and easy to understand, and the control and measurement accessories should be professional and effective.

Budget

Choose moderately priced and cost-effective brewing equipment according to your budget range. Avoid blindly pursuing high-end equipment and causing financial pressure. Before purchasing, learn more about the brands and models of beer brewing equipment on the market and make multi-faceted comparisons and evaluations.

Supplier after-sales service

Choose a manufacturer with a good after-sales service system to ensure that the equipment can receive timely technical support and maintenance services during use. Find out whether the manufacturer provides technical training services for brewers so that they can better master equipment operation and brewing technology.

FAQ

How much does beer brewing equipment cost?

The cost of beer brewing equipment depends on the size, capacity, and required features of the brewery, and can range from tens of thousands of dollars to millions of dollars.

Can the equipment be customized to fit my unique brewing process?

Yes, many manufacturers offer custom equipment solutions to meet specific brewing needs and styles.

What should I look for when purchasing brewing equipment?

Choose high-quality equipment to ensure durability and productivity, and choose a supplier with a good reputation and customer reviews. Make sure the supplier provides adequate after-sales service and support. Choose the right equipment within your budget, taking into account the cost of the equipment and long-term maintenance costs.