One of the important steps to opening a distillery is to start with the correct selection of distillation equipment. If you are an amateur or a professional distiller, understanding the various distillation equipment can allow you to use it better and improve the overall efficiency of distillation. The construction and operation of a distillery involves a lot of equipment and technology. Enterprises need to identify the required equipment to ensure production efficiency, product quality, and production safety. This article will discuss in detail the distillation equipment and other related equipment required by distilleries to help companies that want to invest in distilled spirits production formulate a reasonable equipment procurement plan.

What is distillation equipment?

Distillation equipment is a special machine and device used in the distillation process to separate and purify the components in a liquid mixture. The basic principle is based on the different boiling points between different components. After the liquid is heated to a certain temperature, the volatile components are evaporated and then condensed by cooling to form a high-concentration liquid.

- Heating device: Heats the liquid mixture to reach the boiling point and evaporates the components. It can be electric heating, steam heating flame heating, etc.

- Distiller: The distiller is usually composed of a distillation tower, a condenser, a collector, etc. According to the production scale and demand, the distiller can be divided into a continuous distiller and an intermittent distiller. The intermittent distiller is used for small-batch production and is suitable for a variety of products. The continuous distiller is suitable for large-scale production and can perform distillation operations continuously.

- Separation device: Used to further separate different components to ensure that the target product is obtained. It may include a scrubber, a separator, etc.

- Control system: Monitors and controls key parameters such as temperature and pressure during the distillation process. It may include digital display devices, automated control panels, etc.

Application of distillation equipment

Food and beverage industry

- Alcoholic beverage production: Distillation is an indispensable step in the production process of alcoholic beverages such as liquor, whiskey, vodka, and rum. Through distillation, alcohol can be purified from fermented broth to remove impurities and odors.

- Spice and extracts: Used to extract spices and essential oils from plants, such as vanilla and mint. Distillation can effectively separate aromatic components and improve the purity and flavor of the extraction.

Chemical industry

- Raw material separation: In chemical production, distillation is used to separate and purify various chemical raw materials. For example, in petrochemicals, distillation is used to separate petroleum products with different boiling points, such as gasoline, diesel, and heavy oil.

- Solvent recovery: Distillation can be used to recycle and reuse industrial solvents, thereby reducing production costs and reducing environmental pollution.

Pharmaceutical industry

- Drug refining: Distillation is used in the synthesis and refining of drugs to separate active ingredients (such as active pharmaceutical ingredients) and remove impurities to ensure the quality and efficacy of drugs.

- Solvent removal: In some pharmaceutical processes, distillation is used to remove solvents to ensure that the final product does not contain harmful residues.

Petroleum refining

- Crude oil fractionation: Crude oil can be separated into different components through the distillation process to obtain different types of fuels and chemical raw materials such as gasoline, diesel, kerosene, etc.

- Production of light hydrocarbons: Distillation equipment is used to separate and purify light hydrocarbons (such as propane and butane), and is widely used in the chemical and energy fields.

Environmental science

- Wastewater treatment: In some wastewater treatment processes, distillation is used to recover usable solvents and other components from wastewater and reduce the degree of pollution of wastewater.

- Air purification: Distillation technology is used to remove volatile organic compounds (VOCs) from the air to achieve environmental protection effects.

Bioengineering

In the production of biofuels (such as bioethanol), distillation is used to separate and purify alcohol produced by fermentation for easy use and storage.

What equipment is needed for a distillery?

Mash Tank

The wort tank is the first vessel required in the distillation process. In this vessel, the raw ingredients (e.g. grains such as barley, wheat, or corn) and water are mixed and boiled, which converts the starches into fermentable sugars. Choosing the right wort tank will depend on the size of your business. When a brewery is engaged in smaller activities, a manual or semi-automatic wort tank will do, but for larger breweries, a fully automatic system with temperature and mixing functions is required.

Fermentation Tank

As soon as the mash is ready, it is placed in a fermentation vessel, also known as a fermentation tank. The fermentation tank is where the fermentation takes place. Yeast is added to the mash to convert certain types of sugars into alcohol. Fermentation tanks are usually made of stainless steel because of their strength, simple maintenance, and corrosion resistance. The size and number of fermentation tanks depend on your production volume, but if you plan to expand production, then it is necessary to have enough capacity to handle multiple batches at the same time.

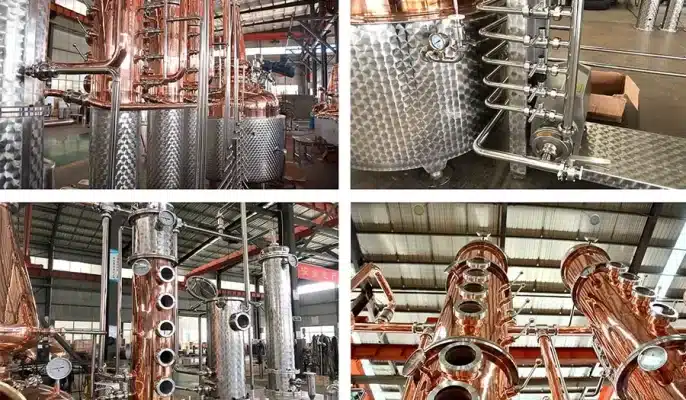

Still

The heart of every brewing system is the still, which heats the liquid mixture so that its parts evaporate at different temperatures. There are two main forms of distiller:

- Pot stills: These are the batch distillation type, often recommended for beginners, and are used to produce spirits such as rum and whiskey. They are friendly to beginners because they are simple in design and easy to operate.

- Column stills: This type of distiller is also called a continuous still and is very effective when it comes to large-scale separations. For example, this piece of equipment will be able to produce high-purity vodka or gin when used for commercial purposes.

Condenser

The condenser is a key component in the distillation process. After the alcohol vapors are heated in the still, the condenser cools these vapors and converts them into liquid. The most common type is the shell and tube condenser, where the vapors pass through a series of tubes surrounded by cold water. The quality and yield of the final product are affected by the performance of the condenser, so the condenser is a very important piece of equipment in any distillery.

Storage tanks

After the product is distilled, it must be stored for a period of time before it can be bottled. Storage tanks are made of stainless steel and are usually used to store distilled spirits during aging or before further processing, flavoring, or proofing. These tanks come in varying sizes and can be customized to your production needs, and can also be equipped with temperature control mechanisms for optimal preservation of the spirit.

Filtration Systems

In order to produce a sufficiently pure distillate, a good filtration system is required. This step in the spirit processing is crucial when producing pure and flavorless spirits such as vodka and gin. Activated carbon filters are often used to absorb unfavorable compounds; however, advanced systems will include multiple stages of filters. The degree of filtration provided will determine how clear, good, and awesome the final product tastes.

Bottling Lines

The final stage of the spirit-making process occurs after the spirit has been distilled and filtered, and if required, aged. This is where the product is bottled. Once the bottles are filled, they must be sealed and labeled before they can be released to the market, all of which is done on a bottling line. A manual bottling line may be suitable for a small distillery; however, as operations expand, a co-location bottling line must be installed. These components may combine the rinsing, filling, capping, labeling, and packaging of the bottles into a single unit.

Pumps and pipes

Pumps and pipes are not often thought about, but they are very important for the movement of various liquids within a distillery. From pumping mash to fermentation tanks, to pumping spirit from the still to storage tanks, pumps need to withstand the ethanol as well as any other solvents or chemicals that flow or are present during the distillation process. This means that the pipes must be made of stainless steel, a material that is corrosion-resistant and easy to clean.

Cleaning equipment

Cleanliness and hygiene within a distillery are very important as it determines the quality of the spirit that is ultimately produced. For example, cleaning equipment such as CIP (cleaning in place) systems help clean tanks, pipes, and stills without having to take them apart. This equipment protects all surfaces that come into contact with the product from contamination, which is very important for product quality and legal requirements.

How to choose distillation and brewing equipment?

Determine the target product.

Make it clear what type of distilled product you want to produce (such as liquor, whiskey, vodka, etc.). Different products may require different types of distillation equipment. Different products have different requirements for purity, so the performance of the equipment needs to be considered to ensure that the required standards can be met.

Choose the type of distillation equipment.

Batch distillation is suitable for small-scale production, flexible operation, and suitable for making high-quality liquor. Continuous distillation is suitable for large-scale production, can maintain continuous production capacity, and is suitable for the production of bulk commodities. Such as traditional boiler distiller, column distiller, etc., selected according to specific needs.

Consider output requirements

Choose equipment of appropriate scale according to the expected production volume to ensure that the equipment can meet production needs. Consider possible future expansion. If you plan to expand production, it will be a wise choice to choose equipment that can be expanded or flexibly configured.

Materials and durability

Materials must be selected from food-grade materials, such as stainless steel, copper, etc., to ensure that there is no contamination to the product and that they are corrosion-resistant. Choose equipment with a sturdy structure, easy to clean and maintain, to reduce long-term operating costs.

Budget and cost

Initial investment evaluates the purchase cost of the equipment and selects the appropriate equipment according to the budget. It is also necessary to consider the maintenance, energy consumption, and labor costs of the equipment to fully evaluate the economic benefits.

Technical support and after-sales service

Choose a reputable equipment supplier to ensure equipment quality and technical support. Understand the manufacturer’s after-sales service terms, including warranty period, technical support, and spare parts supply, to ensure that problems with the equipment can be solved in a timely manner.

Industry standards and certifications

Check whether the equipment complies with relevant industry standards and safety certifications to ensure that the equipment can be put into use legally and safely. Check the reviews and feedback of other brewing manufacturers or users to help judge the performance and reliability of the equipment.