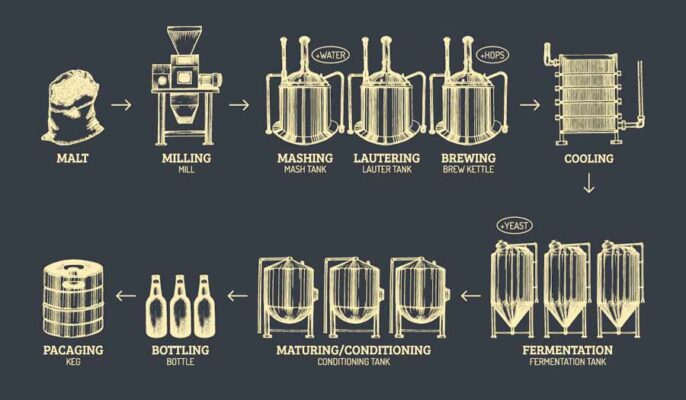

The beer brewing process is both a science and an expression of art. Beer has been a popular beverage for thousands of years, and brewing your own can be a fun and rewarding experience. The brewing process can be broken down into four simplified steps: mashing, separation, boiling and fermentation. The four beer ingredients are brought together at each step to create a wide variety of beer styles. But, if you’re new to brewing, the process can be overwhelming. In this article, we’ll break down the four basic steps in brewing beer.

The Four Key Ingredients for Brewing Beer

- Malt

- Water

- Hops

- Yeast

Beer is always made using the same key ingredients, but the variety and flavor of the beer are affected by different variables throughout the brewing process.

Mash

The first step in brewing beer is called mashing. This is the process of mixing crushed malted grains with hot water to make a sweet liquid called wort. This process is often carried out in a large container called a “Mash Tun”. The starches in the malt are converted into sugars due to the enzymes present in the malt. The wort is then drained and separated from the grain. Mash is a critical step because it extracts the sugars needed for fermentation. This process usually takes 60-90 minutes

Boiled

The wort is transferred to copper, where hops are added for bitterness. The wort is boiled for about an hour, then more hops are added for aroma.

Boiling serves some purposes, it sterilizes the wort and ensures that the yeast can do its job in the fermenter. And stop the enzyme activity in the mash process.

Second, hops also act as an antimicrobial, but more , they impart bitterness, flavor, and aroma to beer. Helps beer last longer.

Fermentation

Once the wort has been boiled and flavored with hops, it’s time to ferment. The yeast is added to the cooled wort, and the mixture is left to rest for days to weeks. The length of the fermentation process depends on the type of beer being produced. When making most beers, the beer is stored for a short period of time at cooler temperatures.

Oxygen is also often introduced at this stage. Yeast is a flavor that can be controlled by the fermentation temperature, the amount of yeast used and the amount of oxygen introduced.

During this time, the yeast consumes the sugars in the wort, producing alcohol and carbon dioxide. The temperature during fermentation is critical as it affects the flavor and quality of the beer.

Bottling and Carbonation

After the fermentation process is complete, alcoholic beer is created. The beer can then be placed in barrels, which is one of the least processed types of beer, or it can be served in barrels, bottles, or cans, which requires processing and carbonation. depending on the style of beer.

If aging is required, secondary fermentation may occur. As the beer continues to ferment in the bottle, carbon dioxide is produced, which handles the fizz in the finished product. During this time, sediment such as excess yeast and protein falls from the beer to the bottom of the bottle.

Brewing beer is a fun and rewarding hobby, and knowing the four basic steps can help you get started. Remember, the key to brewing great beer is attention to detail and patience in the process. With practice and experimentation, you’ll be brewing delicious beer in no time!