Small Batch Brewing Equipment Types

| Equipment |

Description |

| Brew Kettles |

Heats mash liquid to facilitate starch and sugar conversion. Boils sweet wort with hops for aroma and bitterness. Available as direct fire or indirect heat (steam jackets). Sizes from 3 BBL to 7 BBL. |

| Mash Tuns |

Mixes crushed malt with hot water to convert starches to fermentable sugars. Typically insulated stainless steel vessels with false bottom. Sizes between 3-7 barrels. |

| Fermenters |

Ferments sweet wort into beer over days or weeks. Conical or cylindrical stainless steel vessels that are pressure capable and have temperature control. Sizes from 1-7 barrels. |

| Brite Tanks |

Cold conditions and carbonates beer after initial fermentation prior to packaging. Similar vessels as fermenters but focus is clarity and clean flavors. |

| Filtration |

Removes haze particles, hop debris, yeast etc for clarity and stability. Plate filters or centrifuge are common options. |

| Cooling Systems |

Rapidly cools boiled wort and maintains fermentation temp. Glycol chillers and heat exchangers are popular choices. |

| Cleaning / Sanitation |

Critical for sterilizing equipment and preventing contamination. Usually automated CIP spray balls, chemical mixes. |

| Packaging |

Fills beer into bottles, cans or kegs for distribution. Choices range from manual fillers to semi-automatic canning/ bottling lines. |

Small Batch System Sizes

One of the first major decisions that influences equipment selection for a nano or micro brewery is batch size and overall capacity. This depends on business targets for production volume, number of recipes supported and tasting room vs distribution model.

| Batch Size |

Typical System Barrels (BBL) |

Tasting Room or taproom model |

| 1 barrel |

1-3 BBL brewhouse |

Nano brewpub or taproom |

| 3-5 barrels |

3-7 BBL brewhouse |

Microbrewery with tasting room |

| 7 barrels |

7 BBL brewhouse |

Packaging microbrewery with distribution |

- 1 barrel = 31 US gallons = 1.17 hectoliters

- Servings per barrel varies by beer style from 165 to 315 pints

So in terms of capacity, small equates to less than 500 barrels annual production, while large scale is over 50,000 barrels.

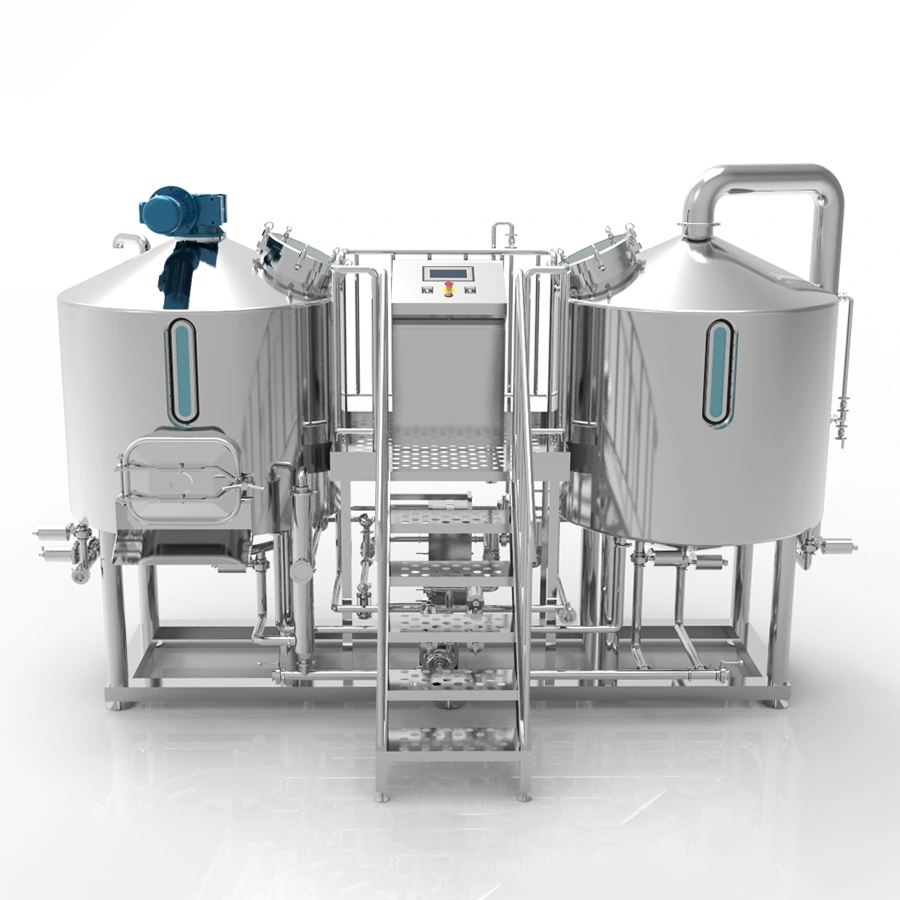

Brewhouse Equipment Considerations

The brewhouse forms the heart of any brewery where the actual brewing takes place. This consists of the hot side vessels for mashing and boiling like kettles and tuns along with wort chilling and transfer systems. Here are some top criteria to evaluate when selecting small batch brewhouse equipment on space, flexibility, automation and pricing.

Key Decision Factors for Nano Brewhouse Equipment

| Parameters |

Description |

| Size |

Depends on batch size and overall volume targets. Aim for some growth capacity. Convert between barrels and liters. |

| Floor Space |

What is the building height and footprint available? Vertical vs horizontal configurations. |

| Flexibility |

Ability to easily vary recipes, ingredients, processes, batch sizes. Customization has a cost. |

| Process Automation |

Level of manual operation vs automated sensors, movements and cleaning. Balancing act of flexibility, cost and quality. |

| Made to Order |

Customized to specifications vs off-the-shelf. Implications on cost, lead time and uniqueness. |

| Quality |

Focus on reliability, repeatability and longevity of vessels and systems selected. |

| Budget |

Overall capital expenditure amount and operating expense over lifetime. Total Cost of Ownership. |

Recommended: Start with a modular, semi-automated 3-7 BBL brewhouse system with room to expand. This optimizes flexibility for small batch innovation while minimizing cost and complexity.

Small Batch Fermentation and Aging Equipment

Once cooled wort has been transferred from the brewhouse, controlled fermentation and aging takes place in stainless steel fermenters and brite tanks. Yeast is pitched into fermenters, converting sugars into alcohol. After active fermentation, beer is transferred to brite tanks for clarifying, carbonating and cold conditioning prior to packaging.

- Cylindroconical fermenters recommended for ease of yeast harvesting

- Direct cooling via glycol or refrigerant lines maintains precise temp control

- Pressure capable vessels allow spunding carbonation technique

- Automated harvesting can reduce off-flavor from yeast contact

| Key Specifications |

Typical Nano/Micro Size Range |

| Number of Vessels |

Depends on number of recipes and seasonal offerings. Start with 3-4 fermenters and 2 brite tanks. |

| Individual Size |

1 BBL to 7 BBL |

| Material |

Stainless Steel grade 316L or 304 |

| Shape |

Cylindroconical or cylindrical |

| Cooling Method |

Glycol, Refrigerant or Cold-room |

| Temperature Range |

32°F to 75°F (0°C to 24°C) |

| Pressure Rating |

60-120 psi design pressure |

| Cone Angle |

60 degrees for ease of yeast harvesting |

| Height/Diameter Ratio |

2:1 to 3:1 ratio optimizes yeast settling |

| Automation Package |

Level sensors, pressure sensors, harvest lines, CIP spray balls |

Recommended: Start with 3xBBL conical fermenters and 2xBBL brite tanks with glycol cooling and harvest lines for a Nano brewery. Choose an automated package to reduce labor and off-flavors.

Packaging Choices for Small Batch Breweries

Once conditioned beer has completed aging in the brite tanks, the final step is packaging into bottles, cans or kegs for serving to thirsty customers. Packaging can be a manual fill process or incorporate semi-automatic labelers, cappers and canners to improve productivity, efficiency and branding.

| Parameter |

Bottling Line |

Canning Line |

Draft Beer Line |

| Throughput Speed |

Slowest, manual |

Faster, semi-automatic |

Fastest, counterpressure filler |

| Labor Requirements |

High, 2+ people |

Medium, 1-2 people |

Low, one person |

| Packaging Material Cost |

Low, reusable glass |

Medium, cans + lids |

Highest, stainless steel kegs |

| Minimum Order Quantity |

Low, custom labels possible |

High, full pallets |

Low, individual keg labels |

| Branding |

High, customized labels |

High, printed cans and lids |

Low, generic kegs |

| Beer Preservation |

Low, oxygen ingress |

Best, airtight and opaque |

Good, but short shelf life |

| Distribution Reach |

Limited, weight concerns |

Wider, durable and portable |

Local, reusable container |

| Price Range |

inquiry now |

inquiry now |

inquiry now |

Recommended: Start with a manual or semi-automatic bottling line for lowest startup cost, customization and distributed reach. Then add a kegging line for tasting room draft followed by cans for retail packaging.