What advantages does Micet Group fully automatic brewing system have?

>What advantages does Micet Group fully automatic brewing system have?

1. Automation level can be selected

The automation level of each order can be customized according to brewer’s needs and budget. Although the automation can be infinitely improved, it is recommended that each customer choose the degree of automation according to their own conditions, such as the most core and The important production process is fully automated, and the auxiliary labor intensity is not high, and manual assistance is also a good choice).

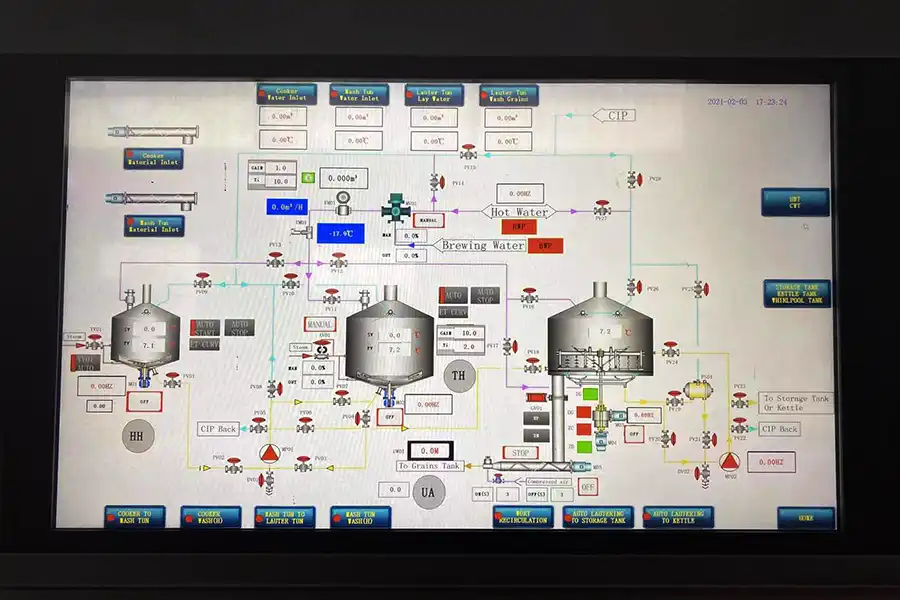

2. One-click start automatic brewing processes visualisation

Variables such as temperature, liquid level, pressure, turbidity, flow, sugar content, valves, pump speed, etc, can be displayed and controlled online. All controllable units can be edited manually. In fully automatic mode, you only need to set all parameters or select a recipe to start and complete all brewing processes with one click.

3. Improve production efficiency and easy for expansion

Micet automated brewery equipment has high production efficiency and high raw material sugar extraction, while maintaining wort quality. It can save time for each batch of wort production, produce one batch of wort in 4 hours and 4 batches of wort in just 10 hours. You can add fermentation tanks directly when need any production expansion in future.

4. Save labor while guarantee beer tastes

It can produce all kinds of beer and is easy to operate, as long as there are formulas and process parameters, which solves the problem of difficulty in finding high-end brewers, as well as the problem of high labor costs in the production process. It is a good choice for beginners who have no brewing experience but are passionate about it.

5. Comprehensive pre-sales and after-sales service

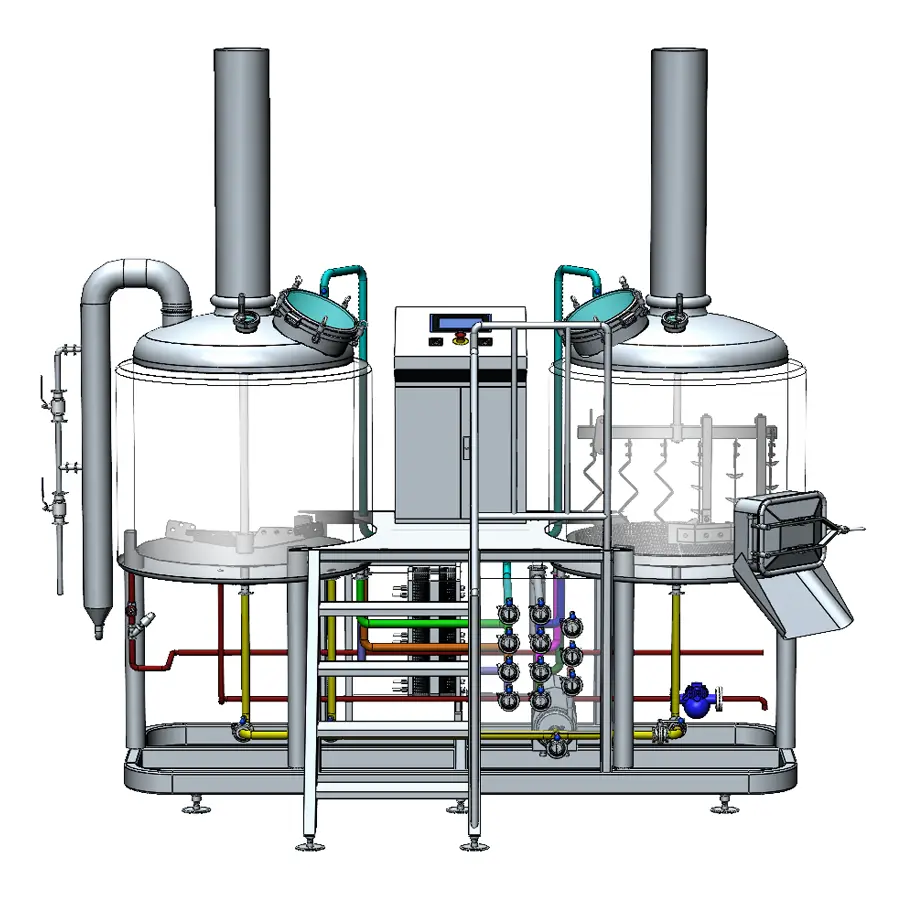

Before purchasing, you can come to our showroom to experience actual operation or online video experience, we provide equipment design in 3D model for cofirmation. Before shipping, we’ll simulate the actual production to test your machine, you can see the testing process throughout the video or come to our factory to personally test machine.

6. Off-site monitoring and remote access

With the site manager installed on your phone, we can use the mobile phone to remotely monitor and understand the progress of fermentation in real-time, you can heat hot water in advance before arriving in brewery. In this case, the brewer’s time is greatly liberated. When you are out, you can open your mobile phone and check the real-time situation of your fermenters. Micet engineers provide remotely installation and debugging, and provide lifetime service, including later upgrades and updates.