In today’s beverage market, the competition between craft beer and commercial beer is becoming more and more fierce. Consumers’ tastes and preferences are becoming increasingly diverse, and many people are beginning to pay attention to the stories behind beer, brewing processes, and unique flavor experiences. The competition between craft beer and industrial beer has always been discussed among beer lovers, brewers, and bar owners. Both have their unique advantages, targeting different customer preferences and experiences. Understanding the nuances and differences between these two beers can help you make an informed decision.

Different definitions

What is craft beer?

Craft beer usually refers to beer produced by small independent breweries. These breweries usually emphasize hand-brewing, the use of high-quality raw materials, and innovative flavors and styles. Craft beer emphasizes diversity, miniaturization, boutique, and localization. Almost all craft breweries must be microbreweries when they start, and many breweries can only be microbreweries forever because of their professionalism. In the United States, the government requires that craft breweries cannot be controlled by industrial breweries, or the shares of industrial breweries cannot exceed 25%.

Features of craft beer:

- Small-scale production: Craft beer is usually made in small breweries with a relatively small production scale, which allows brewers to pay more attention to the quality and uniqueness of each batch of beer.

- Hand-made brewing: Compared with industrialized large-scale production, craft beer emphasizes handcrafts. Brewers will put their heart and soul into every link to ensure the uniqueness and complexity of the flavor.

- Diverse flavors: Craft beer often uses a variety of different malts, hops, and yeasts, and even adds fruits, spices, or other unique ingredients to create a rich and diverse flavor experience.

- Independence: Craft beer is usually produced by independent breweries, which are not controlled by large alcohol groups and maintain autonomy and innovation.

- Culture and community: Craft beer is not only a drink, but also a cultural phenomenon. Many craft breweries actively participate in local community activities, establish close ties with consumers, and create a unique brand story and social atmosphere.

- Quality first: Craft beer pays attention to the quality of raw materials and every detail of the brewing process, and usually pursues higher brewing standards to meet consumers’ high requirements for taste and flavor.

What is commercial beer?

Commercial beer refers to beer produced by large industrial breweries, which usually pursue efficient and large-scale production to meet the needs of the mass market. The focus is on quickly producing large quantities of beer to meet high demand. The selection of raw materials usually focuses on cost-effectiveness and output, and additives and preservatives are sometimes used to extend the shelf life and maintain consistency between batches. Industrial beer has a more uniform taste because the brewing process and style of industrial beer are relatively simple and the fermentation time is short.

Characteristics of commercial beer:

- Scaled production: Commercial beer is usually produced in large-scale breweries to meet the needs of a wide range of markets. This large-scale production makes the cost of each batch of beer lower and the price more competitive.

- Standardized recipe: To ensure consistency in taste, commercial beer uses standardized production processes and recipes. This means that consumers can get a similar taste experience no matter when and where they buy it.

- Wide distribution: Commercial beer is usually widely distributed through large retailers, supermarkets, and catering channels, making it easily accessible in the market and suitable for mass consumption.

- Popular taste: Commercial beer often pursues popular tastes, usually with a light and refreshing style to suit a wider range of consumer preferences.

- Brand awareness: Many commercial beer brands enjoy high popularity in the market and rely on advertising and promotional strategies to attract consumers.

- Economic benefits: The production of commercial beer often pursues efficiency and cost control, which makes it price-advantageous and suitable for consumers with limited budgets.

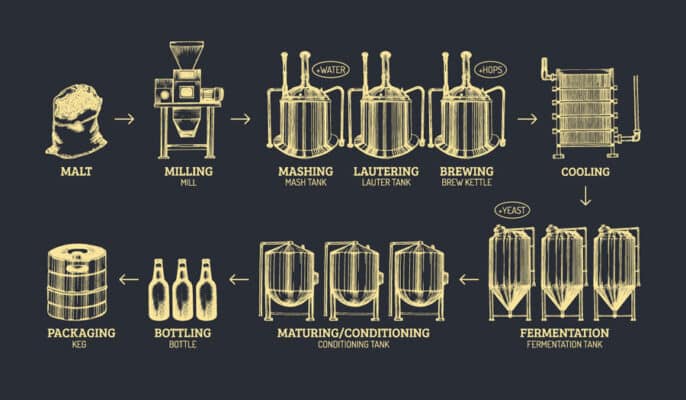

Different brewing processes

Different raw material selection

- Craft beer: Craft brewers often prioritize high-quality and local raw materials. They may use unique Australian hops, native plants, and innovative adjuncts to create unique regional flavors.

- Commercial beer: Rely on optimized standard raw materials to ensure consistency and cost-effectiveness. The focus is on maintaining a uniform taste for large quantities of beer.

- Different brewing scales

- Craft beer: Brewed in small batches, usually on smaller beer equipment, allowing brewers to flexibly adjust recipes and processes.

- Commercial beer: Brewed in large breweries, using automated equipment and efficient production lines to quickly produce large quantities of products.

Different fermentation processes

The fermentation process of craft beer and ordinary industrial beer is also different. Craft beer uses the Ales process (upper fermentation process). Industrial beer uses the Larges process (lower fermentation process). The difference between the two processes is the different locations of the yeast during the fermentation process, and of course, the fermentation temperature is also different. Most craft beers use the Ales process, where the yeast works at the top of the fermentation tank and floats on the liquor. The fermentation temperature is generally controlled at 10-20°C. The fermentation tank is usually small, and no filtration and sterilization are required after fermentation. Most industrial beers use the Lagers process, where the yeast works at the bottom of the fermentation tank and sinks below the liquor. The fermentation temperature is generally controlled below 10°C. The fermentation tank is large, and filtration and pasteurization are usually used after fermentation to increase the shelf life of the beer.

Quality Control

- Craft beer: Due to the uniqueness of each batch of beer, craft breweries will pay more attention to manual monitoring and sensory evaluation to ensure that each bottle of beer meets high standards.

- Commercial beer: Rely on standardized tests and processes to ensure product consistency in mass production, but may sacrifice personalization.

Maturation and packaging

- Craft beer: Usually requires a longer maturation time, and sometimes bottle fermentation is performed to enhance the complexity of the flavor.

- Commercial beer: Shorter maturation time, quick packaging to meet market demand, emphasizing efficient circulation.

Different styles, different nutritional values

Craft beer uses a variety of malt, yeast, and hops, with rich types and quantities, so it can brew a variety of flavors. For example, strong-flavored wheat beer, dark beer, amber beer, and fruit beer. Globally, craft beer is divided into more than 100 styles by type, and generally has the characteristics of strong aroma, high wort content, and mellow taste, so its nutritional value is high. However, the price of craft beer is usually relatively high, and the alcohol content is generally above 11 degrees, and some varieties can even reach 20 degrees.

In contrast, the taste of industrial beer is more uniform. Due to its relatively simple brewing process and style, and short fermentation time, industrial beer has a light taste, rich bubbles, and lower wort concentration. The hop content and alcohol content of industrial beer is usually low, so its nutritional value and price are also relatively low.

Different beer production

Craft beer emphasizes diversification, miniaturization, boutique, and localization. Almost all craft breweries are microbreweries when they start, and many breweries may maintain this scale due to professional limitations. In the United States, the government stipulates that craft breweries cannot be controlled by industrial breweries, and the shares of industrial breweries cannot exceed 25%.

Craft beer usually requires low production, boutique routes, and rich characteristics. The United States stipulates that the annual production of craft breweries shall not exceed 6 million barrels, while the annual production of industrial beer is often more than ten times or more than that of craft breweries. This super-large-scale production will inevitably reduce the requirements for taste because the beer produced by industrial breweries needs to cater to the tastes of most people, so its taste is usually lighter.

Market positioning and target consumers

- Market positioning: Craft beer is usually aimed at consumers who like to try new things and pursue high quality. These consumers are often willing to pay a higher price for unique tastes and personalized brand stories. Commercial beer is aimed at a wider mass market, focusing on sales and market share.

- Consumer culture: Craft beer consumers usually pay more attention to the brewing process, ingredients, and brand stories, and they tend to share their tasting experience on social occasions. Commercial beer consumers may pay more attention to price and availability, and consider more brand awareness and reputation when purchasing.

Conclusion

The difference between craft beer and commercial beer lies not only in the production process and taste but also reflects two different consumer cultures and market positioning. Craft beer attracts many consumers who pursue new experiences with its personalization and diversity, while commercial beer occupies a larger market share with its stability and popularity. In the future, as consumer demand continues to change, the two may develop together in competition and cooperation.