Equipamento de destilação in a brewery is a central component in the production of high-quality spirits, and its design and functionality play a critical role in the quality of the final product. Producers of the finest spirits rely on the functionality and efficiency of the distillation equipment used throughout the process. Distillation is a process that has been used for centuries to separate liquid mixtures based on their boiling points. The process involves heating the mixture to the boiling point and then condensing the resulting vapors to obtain a purified liquid. Finding the right distillation equipment supplier is critical to ensuring optimal performance and reliability.

O que é o equipamento de destilação?

The process of heating a liquid mixture to vaporize its components at different temperatures and condensing them through a pipe at a lower temperature. Most commonly, people use distillation to extract crude oil, alcohol, spices, water, etc. Typically, distillation involves both evaporation and condensation. Therefore, it requires different types of distillation equipment. Distillation equipment performs the distillation process efficiently and effectively. The equipment usually consists of a vessel for heating the mixture, a condenser for cooling the vapor, and a collection vessel for purifying the liquid.

Aplicação do equipamento de destilação

Indústria química

The chemical industry utilizes distillation equipment to purify and separate various compounds. For example, it uses distillation to separate crude oil into different fractions, each with a specific boiling point range. This operation is known as fractional distillation and is used to obtain a variety of petroleum products such as gasoline, diesel, and jet fuel. Distillation is also a common method for purifying solvents, essential oils, and other compounds.

Indústria alimentar e de bebidas

The food and beverage industry utilizes distillation equipment to extract and purify various liquids. For example, it uses distillation to extract alcohol from fermented beverages such as wine and beer. In addition, distillation helps to obtain essential oils from herbs and spices, such as peppermint oil, which is a key ingredient in the production of chewing gum and candy.

Indústria farmacêutica

The pharmaceutical industry utilizes distillation equipment to purify and separate various chemical compounds used in drug production. For example, distillation plays a vital role in purifying solvents and reagents used in drug synthesis. It is also used to obtain purified water for drug manufacturing.

Environmental Industry

The environmental industry utilizes distillation equipment to treat and recycle various waste streams. Distillation plays a vital role in removing contaminants from industrial wastewater and recovering valuable chemicals from waste streams. It is also used to treat hazardous waste before disposal.

Components of equipamento de destilação

Pote de destilação

The distillation pot is the core component of distillation equipment, usually made of stainless steel or copper. It has a large capacity and can hold a large amount of fermented liquor. The interior of the still is usually divided into different segments, each with a specific temperature control and distillation efficiency to help separate the different components of the liquor.

Condensers

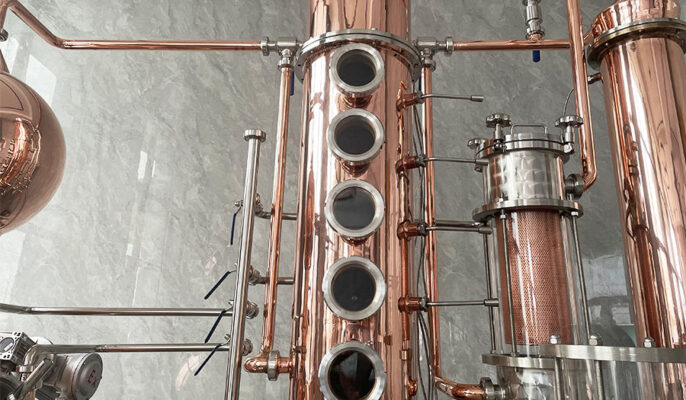

Condensers are critical because they capture the alcohol vapors and return them to the liquid state. In pot stills, the vapors pass through coils or tubes immersed in cold water, where they cool and turn into liquid. In a column still, however, the condenser is contained in the tower. The choice of condenser determines the characteristics of the final product, and a copper condenser is preferred because it removes sulfur compounds, leaving a purer flavor.

Distillation columns

Distillation columns are an essential part of the separation process, consisting of a tower disk or packing, which enables an efficient separation of the components according to their boiling points, and is an essential part of the distillation system. Distillation columns are mainly used as important equipment for separating mixtures into parts or fractions. This separation process is the basis for producing pure components from various mixtures.

Vacuum Pump

This component is essential for decompression distillation, which allows distillation at lower temperatures, which is very beneficial for heat-sensitive substances. The vacuum pump reduces the air pressure in the system and facilitates the evaporation of the components at their respective boiling points.

Reflow System

A reflux unit improves distillation efficiency by recirculating condensed vapors back into the distillation column. This recirculation method improves component separation rates and also increases the purity of compounds required for a variety of industrial applications.

Pressure Control Systems

Distillation pressure control systems monitor and maintain ideal pressure levels during the separation process. These technologies improve the accuracy and efficiency of the distillation process by affecting the boiling point.

Collection Systems

Collection systems include equipment such as collection tanks, piping, and valves that are used to collect and separate the different portions of liquor produced during the distillation process. They ensure that the different stages of the liquor are collected separately to guarantee the purity and quality of each portion.

Heating elements

These can be heating baths, heating jackets, or other heating devices that provide the necessary heat to the evaporating flask. The heating element ensures that the mixture in the flask reaches the temperature required for evaporation.

Types of distillation equipment in brewing

- Simple Distillation Apparatus: The basic distillation apparatus is used to separate components with different boiling points. It is a simple but successful apparatus for a variety of industries and consists of a single distillation column and condenser for efficient evaporation, condensation, and separation of chemicals.

- Fractional Distillation Columns: Fractional Distillation Columns utilize multiple trays or packings, which are critical to separation operations. This innovative configuration increases efficiency by allowing for repeated evaporation and condensation, allowing for the separation of components with similar boiling points in a variety of industrial applications.

- Steam Distillation Equipment: Separate temperature-sensitive components with steam distillation equipment. By injecting steam into the process, the equipment allows for the evaporation of compounds with low thermal stability, providing a precise and standardized procedure for areas such as essential oil extraction and pharmaceuticals.

- Vacuum distillation equipment: Vacuum distillation equipment operates at low pressure, thereby lowering the boiling point of substances. This special arrangement is particularly conducive to the distillation of heat-sensitive materials, ensuring efficient separations in industries where precise temperature control is essential, such as petrochemicals and pharmaceuticals.

What commercial brewing and distilling equipment do you need?

- Storage Tanks: For commercial breweries, it is ideal to start with a standard size 250 gallon/1000L storage tank. Distilling is really about leveraging economies of scale. We accept custom orders for any tank fabrication you desire.

- Wort Tanks: Wort tanks are key vessels in the distilling industry, and wort tanks help convert starches into sugars for fermentation. While not required, we recommend that the wort vat be at least as large as the still.

- Fermentation Tanks: Fermentation tanks are an essential element in the whiskey making process, providing optimal conditions for microbial growth. Micet Group offers a variety of single wall or cooling jacketed fermentation tanks, all made from durable, high-quality stainless steel.

- Kettles: Choosing the perfect kettle starts with deciding on a heating method. Once you have decided on a heating method, you can move on to choosing the size and whether you want a copper top kettle or a stainless steel kettle. For full-flavored whiskeys, a 1000L (264 gallon working capacity) will give you approximately 26 gallons of barrel distillate.

- Still: Depending on whether you want to keep it traditional or separate more flavors, you’ll need to choose between a pot still and a reflux column. A pot still consists of a large pot (kettle), a gooseneck (or Lyne arm), and a condenser.