À medida que o movimento da cerveja artesanal continua a crescer, cada vez mais pessoas estão a considerar abrir uma fábrica de cerveja. Produzir cerveja é emocionante e estamos entusiasmados por ver o sector continuar a crescer. Muitos cervejeiros e amantes de cerveja querem ter a sua própria fábrica de cerveja, e a viagem pode ser stressante. A conceção do layout de uma fábrica de cerveja é uma arte que requer verdadeira habilidade e experiência.

O que é um plano de layout de uma fábrica de cerveja?

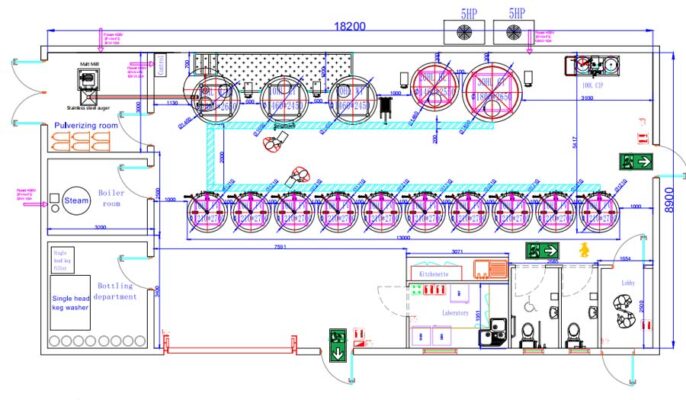

A planta de uma fábrica de cerveja é uma representação gráfica detalhada da localização de todo o equipamento de uma fábrica de cerveja. Fornece uma visão de cima para baixo das instalações, demonstrando o fluxo de trabalho, a gestão do espaço e as considerações logísticas envolvidas nas operações de fabrico de cerveja.

A importância do planeamento do layout

Sem um planeamento adequado do piso, as fábricas de cerveja podem enfrentar problemas como restrições de espaço, fluxos de trabalho ineficientes, aumento do tempo de produção e potenciais riscos de segurança.

- Planeamento do espaço: Assegurar que existe espaço suficiente para todo o equipamento de fabrico de cerveja, desde as caldeiras até aos fermentadores, sem sobrelotação. A utilização correta do espaço também facilita a limpeza, a manutenção e a expansão quando necessário.

- Gestão de processos: Envolve a organização da sequência das operações de fabrico de cerveja para garantir a eficiência. Isto minimiza o movimento e o tempo de espera, resultando num ciclo de fabrico mais rápido.

- Flexibilidade: A disposição de uma fábrica de cerveja bem concebida pode adaptar-se às mudanças, quer se trate da adição de novo equipamento, da expansão da produção ou da integração de nova tecnologia de fabrico de cerveja.

Trabalhos preparatórios antes da instalação da fábrica de cerveja

Antes de estar pronto para montar uma fábrica de cerveja, deve considerar e preparar-se para alguns factores estratégicos e relacionados com o planeamento. Há muitos aspectos a ter em conta antes de começar a experimentar um projeto. Em primeiro lugar, é necessário falar com diferentes cervejeiras, amigos, mestres cervejeiros, fóruns e blogues para compreender que preparação é necessária para iniciar uma cervejaria.

Deve certificar-se de que tem dinheiro suficiente, boas horas de trabalho e um empreiteiro com experiência na construção de cervejarias. A construção de uma fábrica de cerveja, tal como outros projectos de construção, tem sempre custos imprevistos, por isso, certifique-se de que investe alguns fundos extra para ter em conta os custos imprevistos. Naturalmente, também é necessário ter em conta o seu espaço e as modalidades de desenvolvimento viáveis.

Componentes principais da instalação de uma fábrica de cerveja

Os planos de disposição da fábrica de cerveja podem incluir:

| COMPONENTE | DESCRIÇÃO |

| Tina de brassagem | Quando os grãos são esmagados para extrair açúcares fermentáveis. |

| Tanque de fermentação | Local onde o mosto é fermentado para produzir cerveja. |

| Chaleira a ferver | Utilizado para ferver o mosto com lúpulo. |

| Tanque de condicionamento | Para envelhecer e carbonatar a cerveja antes de a embalar. |

A que é que deve prestar atenção ao desenhar a planta de uma fábrica de cerveja?

Uma disposição eficiente e bem concebida da fábrica de cerveja é importante para a segurança e produtividade da mesma. A cervejaria em si é um espaço comercial e os seus passos devem ter em conta a entrada de materiais e mercadorias pela parte de trás da cervejaria para garantir que não impede os clientes de entrarem pela frente da cervejaria para beberem cerveja.

Examinar e determinar as dimensões internas da disposição da sua fábrica de cerveja assegurará a sua eficácia. Além disso, o equipamento da fábrica de cerveja tem questões críticas de altura e largura, que devem ser consideradas ao preparar um projeto de disposição da fábrica de cerveja. Certifique-se de que considera a forma como o seu equipamento será transportado e instalado.

- Existe algum terminal perto de si que possa receber objectos de grandes dimensões?

- Precisa de um empilhador para deslocar o equipamento da fábrica de cerveja e os fermentadores?

Factores a considerar numa planta de uma fábrica de cerveja

- Avalie os seus objectivos de produção: A capacidade da fábrica de cerveja é um fator importante. Está a construir uma nano-cervejaria, uma microcervejaria ou uma megabrevejaria? Determine os seus objectivos de produção a curto e longo prazo.

- Considerar o espaço disponível: Faça uma planta detalhada, anotando colunas, pontos de entrada/saída, janelas e outras estruturas imóveis. Isto dar-lhe-á uma ideia de como organizar o seu equipamento.

- Restrições orçamentais: Considerar o custo da conceção do layout, mas também o custo do equipamento, da construção e de eventuais modificações.

- Considere a eficiência energética: Escolha uma disposição que maximize a luz natural, garanta uma ventilação adequada e minimize os movimentos desnecessários do equipamento.

- Flexibilidade: Assegure-se de que a sua disposição é flexível, permitindo a integração de novos equipamentos ou ajustes nos processos sem causar grandes perturbações.

- Procurar aconselhamento especializado: Embora seja possível conceber a disposição de uma fábrica de cerveja, é fundamental procurar aconselhamento especializado. Micet conhece as últimas tendências e tem uma vasta experiência de projectos anteriores.

Qualquer área da fábrica de cerveja deve poder albergar o equipamento necessário para movimentar as matérias-primas, como um empilhador ou um porta-paletes. Naturalmente, cada área também precisa de uma porta para permitir equipamento para cervejarias para entrar na fábrica de cerveja. Quando a sua cervejaria já não puder acomodar eventos e tráfego, poderá ser necessário reorientar a sua cervejaria.

Pontos-chave do planeamento e conceção de uma fábrica de cerveja

- Planear primeiro, como começar a construir

- Altura e largura do dispositivo

- Problemas de fabrico de cerveja

- Sistema de tratamento por filtração

- tratar as emissões das operações de fabrico de cerveja

- Desenhar um diagrama à escala do espaço de fabrico da cerveja

- Ensaie várias vezes o projeto da sua fábrica de cerveja, tendo em conta a aplicação de cada centímetro da fábrica que está a construir.

- Determinar o local onde os aparelhos serão utilizados

- Coloque o equipamento de fabrico de cerveja apenas na área de fabrico de cerveja e não torne o seu bar demasiado cheio

- Preparação de plantas da fábrica de cerveja para arquitectos

Existem vários factores a considerar quando se prepara uma planta da fábrica de cerveja, como o tipo de pavimento a utilizar? O pavimento é um plano importante que muitos produtores de vinho frequentemente ignoram porque, à partida, pensam que o pavimento é para decoração. Nas áreas activas de produção de cerveja, os pavimentos têm de cumprir as normas de saúde e segurança e têm de ser capazes de resistir ao ambiente agressivo.

Manter a qualidade através da limpeza

Se tomar medidas para garantir que as suas instalações estão limpas e que o seu equipamento de fabrico de cerveja foi concebido para ser limpo, estará protegido contra a contaminação, poupando-lhe tempo e dinheiro. Isto também garantirá a qualidade do produto.

Se está atualmente na fase de conceção do layout da sua fábrica de cerveja, vai querer construir uma fábrica de cerveja que seja fácil de limpar antecipadamente.

Eis algumas dicas para melhorar a limpeza da fábrica de cerveja:

- Discuta com o fabricante do equipamento da sua fábrica de cerveja a melhor forma de colocar o equipamento em cada divisão e determine o melhor método para limpar os tubos e o interior dos tanques.

- As fábricas de cerveja artesanal devem ter pavimentos epóxi não porosos. Uma vez que o pavimento epóxi tem uma camada antimicrobiana na superfície, necessita de menos produtos químicos e de esfregar para limpar, tornando-o fácil de limpar.

- A instalação de um sistema de limpeza no local pode reduzir o potencial de contaminação cruzada durante o funcionamento do equipamento da fábrica de cerveja.

Colocar o equipamento da cervejeira no espaço de conceção

Um pré-requisito para beneficiar do design e da disposição da fábrica de cerveja é saber antecipadamente quais são os seus objectivos e tentar encontrar equipamento e instalações que satisfaçam as suas necessidades. A Micet comunica com os clientes, verificando se estão satisfeitos e se concordam com os resultados das medições. Os designers profissionais da Micet trabalham com os clientes para criar um conjunto complexo de esboços que mostram cada peça de equipamento, até aos mais pequenos pormenores. Isto pode demorar algum tempo, mas é a parte mais importante do processo de produção. Há uma razão para os nossos desenhos CAD serem exactos ao milímetro, porque se não o fossem, poderíamos ter sérios problemas.