In de zeer concurrerende brouwerijmarkt, kleine brouwerij hebben brede steun verworven met hun unieke brouwprocessen en innovatieve smaken. Naarmate de marktvraag groeit, worden deze kleine brouwerijen echter geconfronteerd met een reeks uitdagingen. Hoewel traditionele handmatige en eenvoudige apparatuur de individualiteit en het traditionele vakmanschap van de brouwerij ondersteunt, zijn er duidelijke tekortkomingen op het gebied van efficiëntie en consistentie. De introductie van automatiseringstechnologie biedt deze kleine brouwerijen een reeks oplossingen die ontworpen zijn om hen te helpen de productiviteit te verbeteren en de bedrijfskosten te verlagen door middel van productieprocessen, nauwkeurige en efficiënte kwaliteitscontrole en gestandaardiseerde gegevensanalyse.

Wat is een geautomatiseerd zetsysteem?

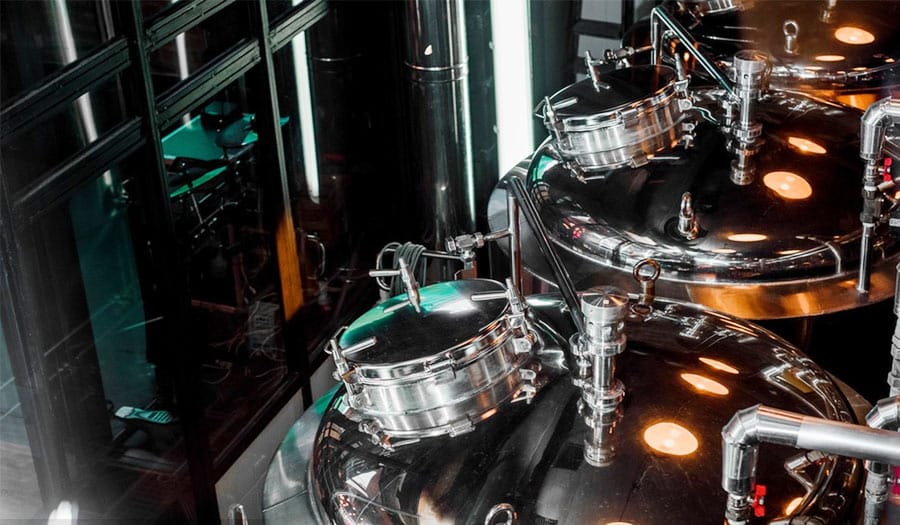

Geautomatiseerd brouwen verwijst naar het gebruik van automatiseringstechnologie om alle aspecten van het bierbrouwproces te controleren en te beheren, waardoor de productie efficiënter verloopt, de kwaliteit van het product constanter blijft en er minder menselijke tussenkomst nodig is. Het geautomatiseerde brouwsysteem integreert geavanceerde technische apparatuur en informatiesystemen om het brouwproces nauwkeuriger, stabieler en efficiënter te maken.

Het brouwproces vereist een delicaat evenwicht van grondstoffen, tijd en omstandigheden. Zelfs de kleinste afwijking kan de smaak, het aroma en de kwaliteit van het bier beïnvloeden. Geautomatiseerde systemen elimineren het meeste giswerk in het brouwproces, waardoor brouwers telkens consistente resultaten kunnen bereiken. Deze consistentie is cruciaal voor commerciële brouwers die willen dat elke partij bier aan de verwachtingen van de klant voldoet. Voor thuisbrouwers betekent het meer succesvolle experimenten en minder verspilling van grondstoffen.

Automatiseringstechnologie in kleine brouwerij

Automatiseringstechnologie in kleine brouwerijen kan de productie-efficiëntie sterk verbeteren, de productkwaliteit garanderen en de benodigde mankracht verminderen. Hier volgen enkele veelgebruikte automatiseringstechnologieën en -toepassingen:

- Automatisering van de verwerking van grondstoffen: Geautomatiseerde transportbanden en pompsystemen kunnen grondstoffen zoals mout en hop van de opslagruimte naar de productielijn transporteren, zodat er minder handmatige handelingen nodig zijn. Gebruik sensoren en controlesystemen om ingrediënten nauwkeurig te batchen om de consistentie van de ingrediënten in elke batch te garanderen.

- Automatisering van brouwprocessen: Geautomatiseerde temperatuurregelsystemen en druksensoren kunnen belangrijke processen zoals het maischen en koken van mout nauwkeurig regelen. Tijdens het beslag en de fermentatie kunnen automatische roersystemen voor een gelijkmatige menging zorgen en de reactie-effecten optimaliseren.

- Automatisering van fermentatie: Gebruik sensoren om de temperatuur, pH-waarde en gasconcentratie in de fermentatietank in realtime te controleren en automatisch aan te passen om ideale fermentatieomstandigheden te behouden.

- Automatisering van vullen en verpakken: Geautomatiseerde afvulmachines kunnen bier efficiënt afvullen in flesjes, blikjes of vaten, wat zorgt voor een nauwkeurige dosering en minder afval. Geautomatiseerde verpakkingssystemen kunnen taken afhandelen zoals etiketteren en verpakken om de algehele efficiëntie van de productielijn te verbeteren.

- Reiniging en desinfectie: Nadat het productieproces is voltooid, kan het automatische reinigingssysteem de brouwapparatuur grondig reinigen en desinfecteren om ervoor te zorgen dat de volgende batch producten niet wordt besmet.

- Gegevensverwerving en -analyse: Het geïntegreerde gegevensverzamelsysteem kan verschillende indicatoren in het productieproces in realtime controleren en suggesties doen voor productieoptimalisatie via gegevensanalyse. Het geautomatiseerde kwaliteitsinspectiesysteem kan snel en nauwkeurig de kwaliteitsparameters van bier detecteren, zoals alcoholgehalte, kleur, schuimstabiliteit, enz.

Wat geautomatiseerde brouwapparatuur heeft een kleine brouwerij nodig?

- Automatisch moutstarter systeem: Meng mout met heet water en onttrek vergistbare suikers aan mout door de temperatuur en tijd te regelen. Dit proces is een belangrijke stap bij het brouwen van bier omdat het het suikergehalte en het uiteindelijke alcoholgehalte van het bier bepaalt.

- Automatisch kooksysteem: Kook het beslag en voeg hop toe om bitterheid en aroma te extraheren. Uitgerust met automatische temperatuurregeling en roerapparaten om een consistente smaak te garanderen.

- Automatisch fermentatietank: De fermentatietank is de belangrijkste apparatuur voor biergisting. Het zorgt ervoor dat gist in de beste omgeving werkt door de temperatuur, druk en gistingsomstandigheden te regelen, waardoor stabiele alcohol en smaak worden geproduceerd.

- Automatisch reinigingssysteem: Het CIP-systeem wordt gebruikt om brouwapparatuur automatisch te reinigen en te desinfecteren, het vervelende handmatig reinigen te voorkomen en ervoor te zorgen dat de apparatuur in een hygiënische staat is voor elke productie.

- Automatisch vulmachine: De automatische afvulmachine is verantwoordelijk voor het nauwkeurig afvullen van bier in flesjes, blikjes of vaten, waardoor een consistente hoeveelheid bier in elk vat wordt gegarandeerd, de handmatige werkzaamheden worden verminderd en de productie efficiënter wordt.

- Automatisch verpakkingssysteem: Het automatische verpakkingssysteem wordt gebruikt om de uiteindelijke verpakking van het afgevulde bier uit te voeren, inclusief etikettering, verzegeling en verpakking.

Voordelen en nadelen van geautomatiseerde brouwsystemen

Voordelen van automatische brouwsystemen

Het belangrijkste voordeel van een geautomatiseerd brouwsysteem is de mogelijkheid om batch na batch bier van consistente kwaliteit te produceren. Deze automatisering vermindert niet alleen het risico op menselijke fouten aanzienlijk, maar is ook van cruciaal belang om de consistente smaak en kwaliteit van het bier te garanderen. Het systeem bespaart ook tijd en moeite, waardoor wijnmakers meer energie aan andere zaken of hobby's kunnen besteden. Bovendien verbetert automatisering de productie-efficiëntie en vermindert het verspilling van grondstoffen, waardoor de productiekosten na verloop van tijd effectief kunnen dalen.

Nadelen van automatische brouwsystemen

Er zijn echter ook enkele nadelen aan automatische brouwsystemen. De initiële investeringskosten zijn hoog, vooral voor geavanceerde commerciële en industriële apparatuur, wat een belemmering kan zijn voor kleine brouwerijen of thuisbrouwers. Hoewel automatisering de behoefte aan handenarbeid vermindert, vereist het bedienen en onderhouden van deze systemen nog steeds een bepaald niveau van technische expertise. Bovendien geloven sommige wijnmakers dat het automatiseren van het proces zou kunnen afdoen aan de ambachtelijke kunstzinnigheid van het brouwen, het hands-on plezier dat voor velen een belangrijk onderdeel is van het brouwproces.

Waarom hebben kleine brouwerijen automatiseringssystemen nodig?

Consistentie

Voor kleine brouwerijen kan het een uitdaging zijn om smaak, kwaliteit en standaarden consistent te houden van batch tot batch. Automatisering zorgt ervoor dat elke stap van het brouwproces nauwkeurig gecontroleerd wordt, waardoor menselijke fouten en variabiliteit geminimaliseerd worden. Dit resulteert in een consistent product, wat essentieel is voor het opbouwen en behouden van het vertrouwen en de tevredenheid van de klant.

Efficiëntie en productiviteit

Automatisering stroomlijnt het brouwproces, waardoor er minder tijd en arbeid nodig is om elke partij bier te maken. Hierdoor kunnen kleine brouwerijen hun productie verhogen zonder de kosten aanzienlijk te verhogen. Geautomatiseerde systemen kunnen repetitieve taken afhandelen, waardoor brouwers zich kunnen concentreren op creatievere activiteiten met toegevoegde waarde.

Gegevensverzameling en analyse

Geautomatiseerde systemen zorgen voor real-time gegevensverzameling en -analyse, wat waardevolle inzichten verschaft in het brouwproces. Kleine brouwerijen kunnen belangrijke parameters zoals temperatuur, druk en debiet controleren om ze snel aan te passen en te verbeteren. Deze gegevensgestuurde aanpak kan de kwaliteitscontrole en procesoptimalisatie verbeteren.

Hoe kies je een leverancier van automatiseringssystemen?

- Technische capaciteiten en ervaring: Kies leveranciers met rijke ervaring en technische mogelijkheden. Ze moeten expertise en succesvolle cases hebben in de overeenkomstige industrie.

- Compatibiliteit van apparatuur: Zorg ervoor dat het systeem van de leverancier compatibel is met bestaande productielijnen en apparatuur om extra kosten en aanpassingen als gevolg van incompatibiliteit te voorkomen.

- Klantenondersteuning en service: De leverancier moet betrouwbare after-sales service en technische ondersteuning bieden, inclusief installatie, training en onderhoud, om een stabiele werking van het systeem op de lange termijn te garanderen.

- Systeemaanpassingsmogelijkheden: Kies leveranciers die oplossingen op maat kunnen leveren volgens specifieke behoeften om te voldoen aan speciale vereisten in het productieproces.

- Feedback en reputatie van gebruikers: Controleer de feedback en evaluatie van andere klanten om de reputatie en productprestaties van de leverancier te begrijpen.

- Kosten en budget: Evalueer de totale kosten van de apparatuur, inclusief initiële investering, onderhoudskosten en bedrijfskosten, om de beste waarde binnen het budget te garanderen.

- Innovatie en upgrade: Kies leveranciers die technologische updates en systeemupgrades kunnen leveren om zich aan te passen aan toekomstige productiebehoeften en technologische vooruitgang.

FAQ

Hoe kunnen geautomatiseerde systemen de productie-efficiëntie verbeteren?

Geautomatiseerde systemen verminderen de handmatige bedieningstijd en menselijke fouten door elk aspect van het brouwproces nauwkeurig te regelen. Geautomatiseerde apparatuur kan productietaken, zoals automatische toevoer, temperatuurregeling, mengen en vullen, continu en snel uitvoeren, waardoor de productiesnelheid en -efficiëntie aanzienlijk verbeteren.

Wat is de initiële investering die nodig is om een geautomatiseerd systeem te implementeren?

Het bedrag van de initiële investering hangt af van de grootte en de complexiteit van het systeem. Automatiseringssystemen voor kleine brouwerijen kunnen een investering van tienduizenden tot honderdduizenden dollars vereisen, inclusief de aankoop van apparatuur, installatie en inbedrijfstellingskosten. Hoewel de initiële kosten hoger zijn, kunnen de kosten op lange termijn worden terugverdiend en bespaard door de productie-efficiëntie te verbeteren en de arbeidskosten te verlagen.

Is het onderhouden en oplossen van problemen met automatiseringssystemen ingewikkeld?

Voor het onderhouden en oplossen van problemen met geautomatiseerde systemen kan enige technische kennis vereist zijn, maar de meeste leveranciers bieden gedetailleerde handleidingen en training. Daarnaast bieden veel leveranciers after-sales service en technische ondersteuning om mogelijke problemen op te lossen en onderhoud uit te voeren.

Welke invloed hebben geautomatiseerde systemen op de smaak en kwaliteit van het wijnmaakproces?

Het geautomatiseerde systeem zorgt voor een consistente biersmaak en -kwaliteit door de temperatuur, tijd en grondstofverhoudingen nauwkeurig te regelen. Er moet echter aandacht worden besteed aan de instelling en het onderhoud van het systeem om ervoor te zorgen dat de smaak en de kwaliteit van het bier niet in het gedrang komen. Automatisering kan ook menselijke fouten helpen verminderen en de stabiliteit van het product verder garanderen.