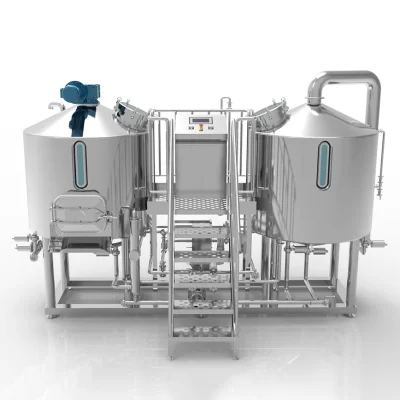

Overview of large scale beer brewing equipment

Commercial beer production requires large scale beer brewing equipment to produce the high volumes needed for distribution and sales. This guide provides a comprehensive look at the end-to-end systems, machinery, tanks, and components that make up a large scale brewery.

Whether you are looking to start your own brewery business or upgrade your existing operations, understanding the full beer production process is essential to choose the right equipment for your goals. We cover the pros and cons of the various options and provide data-driven comparisons to help you make the optimal investments.

This article outlines the core equipment for each stage – from brewhouse to fermentation, conditioning, filtration, and packaging. Technical specifications, standards, installation factors, and operating procedures are detailed in easy-to-use tables. Supplier options are also provided with indicative pricing.

An overview of the key factors to consider when designing and setting up a large scale brewing system is provided below:

Main Equipment in a large scale beer brewing equipment

Brewhouse

- Brew kettle – Mash tun – Lauter tun – Wort kettle – Whirlpool

Fermentation and Maturation

- Fermentation tanks – Maturation tanks

Filtration and Stabilization

- Filters – Pasteurizers

Carbonation and Bright Beer Tanks

- Brite tanks – Carbonation

Packaging

- Bottling line – Kegging line – Canning line

Ancillary Equipment

- Grain handling – Piping – CO2 systems – Cleaning systems – Cooling systems – Boilers – Compressors – Control systems

Key Considerations for large scale beer brewing equipment

- Production Volume – Higher output requires larger brewing vessels and more fermentation tanks. Scale all sections to match target batch sizes and total annual output.

- Floor Space and Heights – Adequate floor space is needed for brewhouse, fermentation room, storage, packaging halls, and warehousing. Optimal layout improves work flows. Ceiling height is critical.

- Utilities – Water, power, steam, compressed air, and wastewater management systems must be set up to supply the brewery.

- Automation – Reduces labor and improves consistency. Consider level of automation from brewhouse to packaging.

- Quality Control – Inline sensors and lab equipment needed to check gravity, alcohol, CO2, microbiology etc. at each stage.

- Budget – Match equipment capabilities and capacities to production goals and financial resources. Prioritize investments for current needs and future expansion.

- Local Regulations – Adhere to regulations on production processes, emissions, wastewater, etc. Get required permits.

By planning your brewhouse, fermentation, filtration, storage, and packaging sections using this guide, you can design an efficient end-to-end brewing system customized for your specific requirements.

Brewhouse Equipment

The brewhouse is where the magic of beer brewing begins. This section covers the essential vessels and machinery needed to produce wort – the sweet liquid extracted from malt that gets fermented into beer.

Key Functions of the Brewhouse

- Milling – Crushing malt into grist

- Mashing – Mixing grist with hot water for starch conversion

- Lautering – Separating sweet wort from spent grains

- Wort boiling – Sterilizing, extracting flavors, coagulating proteins

- Whirlpooling – Settling trub before fermentation

Malt Handling Equipment

Malt Silos

Malt silos store whole grain. Different silos used for base malts and specialty malts. Volume depends on production and frequency of deliveries.

Malt Mill

- Roller mill crushes malt into grist for mashing

- Two or four roller configurations

- Rollers have fluted or smooth surfaces

- Gap between rollers sets coarseness of crush

- Malt is fed automatically from silos

- Optimize crush for maximum extract but avoid flouring

Grist Case

- Holds freshly milled grist between the mill and mash tun

- Keeps grist contained and allows buffer time for milling and mashing

- Various capacities matched to batch volumes

Screens

- Remove small particulates from grist before mashing

- Prevent lauter tun issues and extraction inefficiencies

Grist Hydrators

- Optional – Mix grist with water before adding to mash tun

- Improves extraction by hydrating husks before mashing

Grist Weighers

- Weigh batches of grist for recipe formulation

- Automated weighing improves consistency and reduces labor

Grist Transport System

- Enclosed screw or pneumatic conveyors

- Quickly transport grist to mash tun

| Type | Capacity | Power | Size | Price Range |

|---|---|---|---|---|

| Malt silo | 5 – 500 metric tons | N/A | Match storage needs | $5,000-$500,000 |

| Roller mill | 1 – 50 metric tons/hr | 15 – 250 kW | Varies | $5,000-$250,000 |

| Grist case | 1 – 250 hl | N/A | Varies | $5,000-$100,000 |

| Grist hydrator | 1 – 100 metric tons/hr | 1 – 250 kW | Varies | $1,000-$100,000 |

| Grist weigher | 50 – 5000 kg batches | N/A | Varies | $5,000-$50,000 |

| Grist transport | 10 – 200 metric tons/hr | 1 – 10 kW | Varies | $5,000-$100,000 |

Mashing Equipment

Mash Tun

- Mixes grist with hot water in sequence to convert starch into fermentable sugars

- Stirring system for uniform temperature and conversion

- Insulated to maintain desired mash temperature

- Steel or copper construction

- Separates sweet wort from spent grains

Mash Filter

- Alternative to lauter tun

- Faster lautering using pressure and filtration

- More compact design

- Lower extraction efficiency (~2% less)

- Higher capital and operating costs

Mash Pumps

- Recirculate wort through grain bed for clarity and efficiency

- Maintain desired flow rates and temperatures

- Various pump types used – centrifugal, PD, turbine

Heat Exchangers

- Heat water used for mashing and sparging

- Steam-based or electric systems

- Maintain tight temperature control

Mixing Systems

- Mixing rakes, paddles, or jets

- Important for uniform mash conditions

- Reduce dough balls and temperature gradients

| Type | Capacity | Power | Size | Price Range |

|---|---|---|---|---|

| Mash tun | 5 – 250 hl/batch | 10 – 500 kW | Varies | $50,000-$1,000,000 |

| Mash filter | 10 – 250 hl/batch | 15 – 250 kW | Smaller | $100,000-$1,500,000 |

| Mash pump | 10 – 250 m3/hr | 2 – 250 kW | Varies | $1,000-$100,000 |

| Heat exchanger | 50 – 5000 kW | Steam or electric | Varies | $10,000-$500,000 |

| Mixing system | Tun dependent | 1 – 50 kW | NA | $10,000-$100,000 |

large scale beer brewing equipment

Lauter Tun

- Traditional tun with false bottom to separate wort

- Rakes for grain bed conditioning

- Spray nozzles for sparging

- Longer lautering time

Mash Filter

- Covered above – faster filtration alternative

Wort Grant

- Collects clear wort from the lauter tun

- Level and flow instruments for automated control

- Pipes transfer wort to kettle

Sparge Arm

- Distributes hot water evenly over grain bed

- Improves extraction efficiency

- Spray nozzles designed to avoid channeling

Wort Pumps

- Transfer wort post-lautering to kettle

- Centrifugal or PD pumps used

- Flow and pressure control instruments

| Type | Capacity | Power | Size | Price Range |

|---|---|---|---|---|

| Lauter tun | Brew length | N/A | Varies | $50,000-$1,000,000 |

| Wort grant | Tun dependent | N/A | NA | $10,000-$50,000 |

| Sparge arm | Varies | N/A | NA | $1,000-$10,000 |

| Wort pump | 10 – 250 m3/hr | 2 – 250 kW | Varies | $1,000-$100,000 |

Wort Boiling Equipment

Brew Kettle

- Boils wort to extract flavors, sterilize, and coagulate proteins

- Steam or direct fire heating

- Internal calandria or external boiler

- Various shapes – cylinders, tun shapes, pans

- Agitators for mixing and boiling action

Whirlpool Vessel

- Separates protein trub and hops

- Swirl action for trub cone formation

- Reduces carryover into fermenters

- Can be integrated with brew kettle or separate tank

Wort Aerator

- Aerates cooled wort before yeast pitching

- Needed for healthy fermentation

- Various designs – subsurface mixers, venturi, nozzle-based

Heat Exchangers

- Cool hot wort to fermentation temperature

- Plate heat exchangers or shell and tube

- May be combined with wort aerator

Pumps

- Wort pumps – transfer to whirlpool and heat exchangers

- Various types – centrifugal, PD, lobe

| Type | Capacity | Power | Size | Price Range |

|---|---|---|---|---|

| Brew kettle | 5 – 250 hl batches | 50 – 5000 kW | Varies | $50,000-$2,000,000 |

| Whirlpool | Matched to kettle | Small | NA | $10,000-$500,000 |

| Wort aerator | 1000 – 100000 hl/hr | 2 – 250 kW | Varies | $1,000-$100,000 |

| Wort cooler | 1000 – 100000 hl/hr | 50 – 5000 kW | Varies | $10,000-$1,000,000 |

| Wort pump | 10 – 250 m3/hr | 2 – 250 kW | Varies | $1,000-$100,000 |

Brewhouse Control Systems

- Automated recipe management and batch control

- Integrates motors, valves, sensors, flows, levels, and temperatures

- Improves efficiency, consistency, reporting, and compliance

- Options range from basic to advanced functionality

| Type | Capabilities | Price Range |

|---|---|---|

| Manual | Basic gauges only | N/A |

| Semi-auto | Basic sequence control | $10,000-$50,000 |

| Automatic | Advanced run screens, data capture | $50,000-$500,000 |

Fermentation and Maturation Equipment

Fermentation transforms wort into beer over days to weeks through yeast activity. Maturation further conditions and clarifies the beer prior to packaging. The key vessels in this section are:

Fermentation Tanks

Function

- Ferments wort into beer

- Closed, oxygen-free environment for pure yeast activity

- Temperature control for optimal fermentation

Types

- Cylindrical – Most common, lower surface to volume ratio, cone or flat bottom, height can exceed diameter for volume

- Square – More compact footprint, challenging drainage, limited availability

- Open – Older, allows natural yeast capture, risk of contamination, rarely used for large breweries

Construction

- Stainless steel is standard – durable, impermeable, corrosion resistance, hygienic

- Special alloys offer improved corrosion resistance

Sizes

- Scale total tank volume and number of tanks to match batch and annual volumes

- Individual tanks can range from 50 hl to 2500 hl

- Optimal size balances flexibility and economy of scale

Temperature Control

- Jackets for heating/cooling using glycol or other heat transfer fluids

- Adjustable based on yeast strain and beer type

- Tight control improves quality and consistency

Yeast Management

- Bottom cone with valve for yeast slurry removal

- Top manways for dry yeast pitching

| Type | Capacity | Height/Diameter | Price Range |

|---|---|---|---|

| Cylindrical | 50 – 2500 hl | 1:1 – 4:1 H:D | $10,000 – $500,000 |

| Square | 50 – 2500 hl | NA | $10,000 – $500,000 |

Maturation Tanks

Functions

- Ages beer after primary fermentation

- Clarification and flavor development

- Carbonation for cask ale or secondary fermentation

Design and Options

- Similar stainless steel cylindrical tanks with conical bottom

- Jacketed for temperature control

- Mild agitation improves conditioning and clarity

- Unsure conditioning requirements? Install smaller tanks first.

Brites and Unitanks

- Combines fermentation, maturation, and storage

- Reduces transfers and risk of oxygenation

- Higher capital cost but operational advantages

- Best for consistent products

| Type | Capacity | Price Range |

|---|---|---|

| Maturation only | 50 – 2500 hl | $10,000 – $500,000 |

| Brite/unitank | 50 – 2500 hl | $15,000 – $750,000 |

Yeast Management Systems

- Yeast storage tanks – maintains yeast supply

- Pitching and cropping stations – handles transfer to fermenters

- Monitoring – checks viability and purity

- Propagation – grow-up systems for pitching

- Automation reduces open handling.

Filtration and Stabilization Equipment

Various filters and equipment help clarify beer, adjust carbonation, ensure microbial stability, and prepare bright beer for packaging.

Filtration

Types

- Precoat – Kieselguhr and perlite medium

- Plate and frame – series of membrane plates

- Centrifugal – spinning sedimentation

- Crossflow – ceramic membrane filtration

Characteristics

- Remove yeast, haze particles, colloids

- Adjust level of clarification from coarse to sterile

- Balance removal efficiency, throughput rate, maintenance needs

Operation

- Multiple stages from coarse to final clarification

- Pre-filters protect finer membranes

- CIP systems clean between batches

| Type | Throughput | Price Range |

|---|---|---|

| Precoat | 50 – 500 hl/hr | $50,000 – $500,000 |

| Plate and frame | 10 – 250 hl/hr | $20,000 – $250,000 |

| Centrifugal | 10 – 250 hl/hr | $50,000 – $750,000 |

| Crossflow | 10 – 250 hl/hr | $75,000 – $1,000,000 |

Pasteurization

- Heats beer to sterilize and stabilize

- Typically 60-90°C for 15-60 minutes

- Better flavor stability than filtration alone

- Tunnel or plate-based systems

Carbon Dioxide Removal

- Strips excess CO2 before packaging

- Prevents overcarbonation and foaming

- Degassing columns with vacuum, temperature, pressure control

Carbonation

- Adds CO2 for packaged product

- Brite tank carbonation

- Inline carbonation during filling

- Level depends on product style

Bright Beer Tanks

Conditioned beer is transferred to bright tanks prior to packaging.

- Chilled storage awaiting packaging

- Clarification through settling

- Carbonation to style specification

- Protection from air and contamination

Bright Tank Types

- Cylindrical – Standard for beer storage

- Variable Pressure – Carbonation control capability

- Brites – Combined fermentation and bright functions

Size and Quantity

- Total volume based on production, packaging schedule

- Individual tanks from 50 – 1000 hl

- Multiple tanks for flexibility and cleaning cycles

Features

- ASME pressure rating

- CIP spray balls

- CO2 injection and mixing

- Cooling jackets

- Level sensors

| Type | Capacity | Price Range |

|---|---|---|

| Cylindrical | 50 – 1000 hl | $10,000 – $250,000 |

| Variable pressure | 50 – 1000 hl | $15,000 – $500,000 |

| Brite/unitank | 50 – 1000 hl | $15,000 – $750,000 |

Packaging Equipment

Packaging lines fill beer into barrels, kegs, cans, and bottles at high speeds.

Bottling Line

Key Components

- Bottle washer – cleaner and sanitizer

- Filler – automated counterpressure filling valves

- Capper – presses caps onto filled bottles

- Labeller – front, back, neck labels

- Packer – cases filled bottles

Line Speed and Automation

- Up to 120,000 bottles per hour (1500 cases/hr)

- High degree of automation

- Servo motors and variable frequency drives

Inline Quality Control

- Fill level, cap inspection, label inspection

- Rejects bottles with defects

- Reduces waste

Changeover

- Toolless changeover kits enable quick product changeovers

- Reduce downtime between production runs

Keg Line

Function

- Fills stainless steel or plastic kegs

- Counterpressure fill valves

- Automated handling and conveying

Line Speed

- Up to 800 kegs per hour

- Singles or twins configuration

- High degree of automation

Components

- Keg washer – clean and sterilize

- Purger – CO2 purge of empty kegs

- Filler – counterpressure valves

- Crowner – presses sanitary seals into kegs

- Labeler – applies labels during conveyance

Changeover

- Flexible lines can handle multiple keg sizes

- Quick disconnects enable fast product changeovers

| Output | Price Range |

|---|---|

| 100 – 800 kegs/hr | $ |

Canning Line

Function

- Fills cans at high speeds

- Pre-made cans fed into filer

- Seamer seals cans after filling

Line Speed

- Up to 2000 cans per minute

- High automation with servo drives

Components

- Unpacker – removes cans from pallets

- Rinser – interior spray cleans cans

- Purger – CO2 purge of empty cans

- Filler – volumetric filling valves

- Seamer – rolls and presses can lids

- Leak detection – rejects defective cans

- Labeler – front and back labels

- Packer – group and overpack cans

Changeover

- Format change parts for flexibility

- Toolless disconnects enable rapid changeovers

| Output | Price Range |

|---|---|

| 10000 – 100000 cph | $ |

Clean-In-Place Systems

Automated cleaning systems for packaging line hygiene.

- Detergent tanks, pumps, valves, spray balls

- Programmed cycles for cleaning, rinsing, sanitizing

- Reduces manual cleaning labor

Palletizers

Stacks filled cases or cans onto pallets

- High speed robotic palletizing

- Pallet dispensers, lifts, and conveyors

- Automatic wrapping in stretch film

Pasteurizers

- Final product pasteurization before packaging

- Improves shelf life and flavor stability

- Alternative to sterile filtration

Ancillary Systems

Beyond the core equipment, large breweries require extensive infrastructure and utilities.

Grain Handling

- Conveyors – move raw materials into the brewhouse

- Bucket elevators, screw augers, air slides

- Magnets, screens – remove foreign matter

Piping

- Interconnects vessels and transfers products

- Stainless steel for hygiene and corrosion resistance

- Sloped for drainage, avoid dead legs

- Flexible connections absorb vibration

CO2 Systems

- CO2 storage tanks, vaporizers, manifolds

- Distributes CO2 for carbonation, purging

- Pressure regulators and safety valves

CIP Systems

- Clean-in-place – automated cleaning of equipment

- Detergent tanks, pumps, valves, heaters

- Scheduling and monitoring software

Cooling Systems

- Chilled water loop, cooling towers, pumps, valves

- Glycol chillers for jacketed tanks

Boilers

- Generate steam for heating applications

- Natural gas or biomass-fired boilers

- Redundancy for uptime critical needs

Compressed Air

- Runs pneumatic actuators and controls

- Air compressors, dryers, filters, distribution

Wastewater Treatment

- Handles process effluents and brewhouse wastes

- Screens, clarifiers, biological treatment, sludge dewatering

Electrical Infrastructure

- Incoming power supply redundancy

- Distribution through bus bars and cables

- Emergency backup power generators

Process Control System

- Automated monitoring and control of brewing

- Integrates instruments, valves, motors, drives, HMIs

- Recipe management, batch reporting, analytics

How to Select a large scale beer brewing equipment Supplier

Choosing the right brewhouse OEM is key to executing your brewery project successfully. Here are the key factors to consider in your selection process:

Reputation and Experience

- Proven track record designing and building brewhouses

- Check references from existing customers

- Experience with your production scale

Quality and Support

- High quality manufacturing and rigorous testing

- Responsive after-sales service and support

Technical Expertise

- Qualified engineers to design the system

- Ability to optimize the brewhouse design for your needs

Client Focus

- Understands your production goals, budget, and constraints

- Flexible approach focused on your specific requirements

Automation Capabilities

- Sophisticated brewhouse control systems

- Ease of use, data reporting, and connectivity

Global Presence

- Sales and service support in your geography

- Compliance with local codes and regulations

Delivery Reliability

- Proven ability to deliver projects on-time

- Attention to schedules and coordination

Value for Money

- Balance of quality, performance, and fair life cycle cost

- Get quotes from multiple vendors

By comparing multiple brewhouse OEMs on these parameters, you can make the optimal choice for your new brewery.

Pros and Cons of Brewhouse Systems

Steam Heating vs Direct Fire

- Steam boilers offer centralized heat source but high capital cost

- Direct fire gives brewhouse independence but needs burner management

Internal vs External Boiling

- Internal calandria is compact but can limit kettle sizes

- External boiling allows flexibility but needs additional boiler

Mash Tun vs Mash Filter

- Mash tun is traditional design with full extract potential

- Mash filter faster lautering but slightly lower extraction

Whirlpool vs Centrifuge

- Whirlpool simple and gentle but larger footprint

- Centrifuge compact but delicate pellets

Manual vs Automated

- Manual lower cost but intensive labor needs

- Automation improves consistency but adds complexity

There are always trade-offs to consider. Choose based on your production requirements, budgets, and operating philosophy.

FAQ

What are the typical floor space needs for a large brewery?

A 50,000 hectoliter per year brewery needs around 27,000 – 40,000 sq. ft for the brewhouse, fermentation room, storage, and packaging hall. Warehousing adds additional space needs. In general, allocate around 0.5 – 1 sq. ft. per annual hectoliter.

What ceiling height is recommended for a brewery?

For material handling, a minimum clearance of 20 ft is recommended from finished floor to ceiling. Ideally 25-30 ft for larger breweries. This accommodates equipment height plus overhead utility pipes and cables.

How much water is required for commercial beer production?

On average 4 – 10 hl of water is used to produce 1 hl of beer including all processing steps. Larger breweries can achieve 4-6 hl/hl with efficient use and recycling. Monitor water usage and target reductions through best practices.

How many fermentation tanks should a brewery have?

As a rule of thumb have 2 – 3 turns per year per tank or more, to keep capital costs reasonable. For example, for 50,000 hl annual volume, use 15-25 tanks of 2000 hl each for flexibility. The ideal number depends on production schedule, beer types, sales patterns, and packaging.

What are the highest cost pieces of brewery equipment?

The brewhouse vessels, fermentation tanks, special process filters, and packaging lines involve the highest capital investments. Prioritize these based on immediate production needs and future growth plans. Invest in reliability and quality for critical assets.

How much power does a brewery require?

A moderately sized brewery uses around 100-150 kWh per hectoliter produced. Larger breweries can average 50-100 kWh/hl with energy efficiency measures. Natural gas needs are around 20-40 MJ per hl. Conduct an energy audit and install sub-metering to optimize usage.

How many people are needed to staff a large brewery?

For a 50,000 hl brewery, around 25-45 people are needed for brewhouse, fermentation, filtration, packaging, maintenance, warehouse and lab roles. Larger breweries achieve under 1 operator per 1000 hl. Automation reduces direct labor needs.