What Makes Stainless Steel Tanks the Best Choice for Storage?

안전한 보관을 위한 내구성 있고 위생적인 솔루션

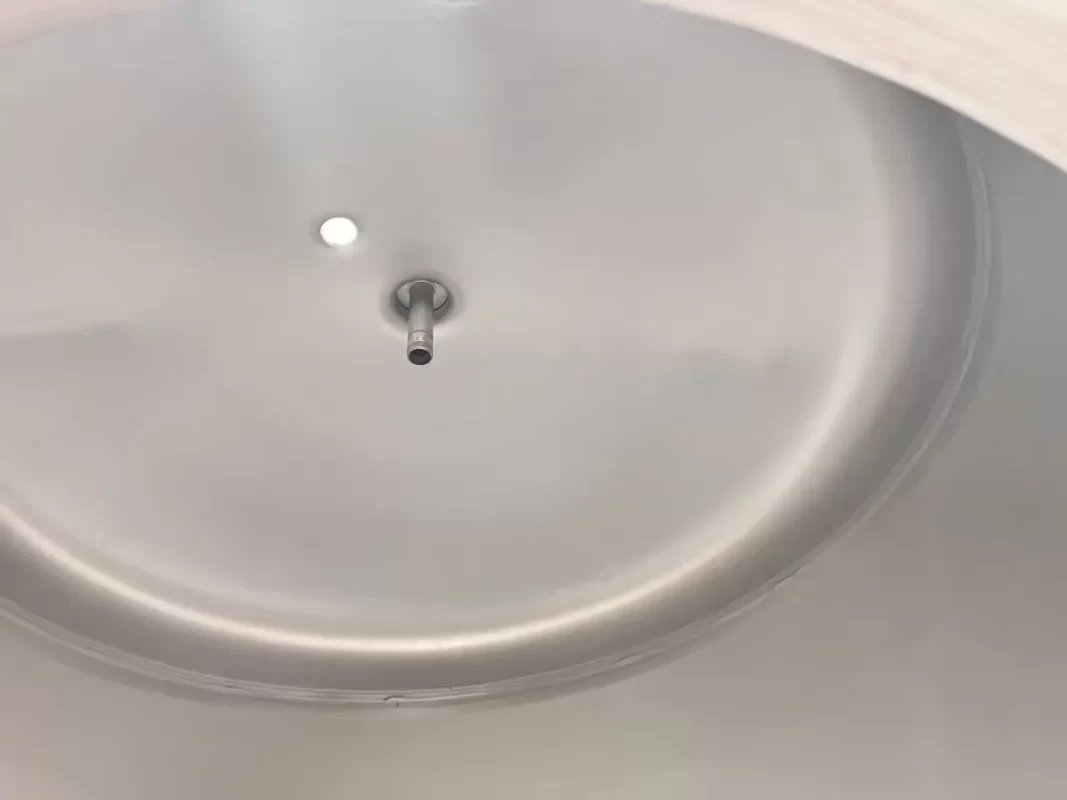

미셋 그룹은 최대 30,000L의 작업 용량에 맞게 설계 및 제조된 다양한 스테인리스 스틸 산업용 저장 탱크를 공급합니다. 이 탱크는 SUS304 또는 SUS316L 스테인리스 스틸, 단층 또는 가열 및 냉각 재킷으로 단열된 완전 용접 스테인리스 스틸로 공급할 수 있습니다. 스테인리스 스틸 탱크는 압력 등급을 받을 수 있으며 ASME 압력 용기 표준에 따라 제작됩니다. 모든 저장 탱크는 상단 맨홀, 측면 입구 또는 바닥 장착형 교반기를 장착할 수 있으며, 교반기를 용기 위에 장착하거나 바퀴로 움직일 수 있도록 개방형으로 제작할 수도 있습니다.

이러한 산업 저장 탱크 식음료, 오일, 잉크 및 페인트, 화학, 화장품, 제약, 농업 등 다양한 산업에서 사용할 수 있습니다.

재질

부식에 강하고 오일 순도를 유지하는 고품질 스테인리스 스틸

밀폐형 뚜껑

밀폐 커버로 공기 노출을 방지하고 오일의 신선도 유지

배수 밸브

간편한 디스펜싱과 효율적인 오일 관리를 위한 하단 배수 밸브

내마모성

바쁜 주방 및 산업 환경에서 일상적인 사용으로 인한 마모와 손상을 견뎌냅니다.

What Sizes are Available for Stainless Steel Storage Tanks?

We offer a 다양한 크기 to meet diverse storage requirements. Standard capacities include 200-gallon, 300-gallon, and even larger bulk tanks. For those needing something specific, we provide custom storage tanks tailored to your capacity and space specifications. Whether you need a compact solution or a large stainless steel tank, we’ve got you covered.

주요 기능:

견적 요청하기고품질 스토리지 탱크

10000L 저장 탱크

10000L 저장 탱크

20000L 화학물질 저장 탱크

20000L 화학물질 저장 탱크

20000L 저장 탱크

20000L 저장 탱크

20000L 저장 탱크

20000L 저장 탱크

10000L 저장 탱크

10000L 저장 탱크

500L 적층형 수평 탱크

500L 적층형 수평 탱크

The Role of Fabrication in Ensuring Tank Quality

우리 회사에서 만든 다양한 유형의 저장 탱크는 다양한 산업 분야에서 실용적인 응용 분야를 찾습니다. 그 기능은 재료의 종류와 밀접한 관련이 있으며, 안전은 제조업체로서 우리가 가장 중요하게 생각하는 측면 중 하나입니다.

장인 정신 쇼

How Do Stainless Steel Storage Tanks Benefit the Chemical Industry?

In the 화학 처리 sector, the need for safe and reliable storage solutions is paramount. Stainless Steel Storage Tanks are preferred because they can handle a wide range of chemicals without reacting or degrading. These tanks are used to store acids, bases, and other corrosive substances safely, ensuring operational efficiency and worker safety.

Our expertise in fabrication guarantees that each tank meets the highest quality standards. Utilizing state-of-the-art technology, our fabricators craft tanks that not only meet but exceed industry expectations. This dedication to quality ensures that our tanks are manufactured to provide long-lasting service with minimal maintenance.

304 스테인레스 스틸 is widely used due to its excellent 내식성 and cost-effectiveness. 316 스테인레스 스틸 contains molybdenum, enhancing its resistance to chlorides and making it suitable for harsher environments.

Yes, we specialize in custom tank solutions. Whether you need a unique size, shape, or feature, we can build tanks that align with your specific requirements.

Maintenance is straightforward—regular cleaning with a mild detergent and water rinse is usually sufficient. This helps maintain the tank’s appearance and prevents any buildup that could affect performance.

마이셋 스토리지 탱크의 장점

- 리프팅 이어가 있는 저장 탱크 디자인으로 장비를 제자리에 쉽게 들어올릴 수 있습니다.

- 제품에 따라 쿨링 재킷이 있는 단일 벽면 또는 이중 벽면 디자인.

- 냉난방 효율을 보장하기 위해 특별히 설계된 딤플 재킷.

- 커버 헤드스페이스 볼륨은 별도로 계산되어 추가됩니다.

- 고객의 필요에 따라 측면 맨홀 또는 상단 맨홀을 선택할 수 있습니다;

- 재킷 테스트는 공기와 물로 12시간 동안 진행되며, 재킷 테스트 압력은 5Bar입니다,

- 내부 쉘 테스트 압력은 4Bar이며, 포장 전 48시간의 수압 테스트를 거칩니다.

- 압력 테스트 인증서 및 테스트 데이터는 탱크 데이터 플레이트에 표시됩니다;

- 광택/브러시/미러 마감/산세 패시베이션은 선택 사항입니다.

- 모든 탱크에는 조정 볼트가 장착되어 있어 탱크를 정렬하고 수평을 맞출 수 있습니다.