Your dream brew deserves flawless fermentation, yet many startup breweries lose beer to leaks, corrosion, or poorly welded tanks. That pain stings profits and reputations, turning the excitement of brewing into a constant battle against equipment failure. Imagine the frustration of dumping a batch due to contamination traced back to a microscopic weld flaw, or the operational nightmare of managing inconsistent fermentation temperatures. Our precision-built stainless steel conical fermenters fix the problem—batch after batch, sip after sip, providing the reliable foundation your brewery needs to thrive.

A beer fermentation tank is the sealed vessel where wort becomes beer. It’s more than just a container; it’s a carefully engineered environment that nurtures yeast and transforms simple sugars into a complex tapestry of flavors and aromas. A food-grade, conical, stainless steel fermenter provides yeast with an optimal environment for a clean fermentation process, easy yeast harvesting, and a swift switch from primary fermentation to maturation—all while preserving aroma and flavor.

What is a Beer Fermentation Tank and Why Does It Matter?

A 발효 탱크—also called a beer fermenter—is the critical arena where wort transforms into beer. Yeast consumes sugars, releasing alcohol, carbon dioxide, and flavor compounds. Controlled conditions inside the tank dictate the beer’s final taste and quality.

Professional fermenters feature a 60-degree conical bottom, allowing yeast and sediment to concentrate at the apex. This design simplifies trub removal and yeast harvesting, ensuring minimal beer loss.

Our manufacturing plant has refined tank production for over two decades, adhering to ASME and EHEDG standards. We utilize orbital TIG welding, polishing interiors to a mirror finish, preventing contamination.

Key Benefits

Conical bottom ensures effective sediment collection and clarification.

Insulation and cooling jackets stabilize fermentation temperatures within ±0.2 °C.

CIP pipe and 360° cleaning nozzle cut cleaning labor by up to 35%.

Explore full details in our 스테인리스 스틸 발효 탱크 및 브라이트 탱크.

How Does Tank Geometry Affect Fermentation Quality?

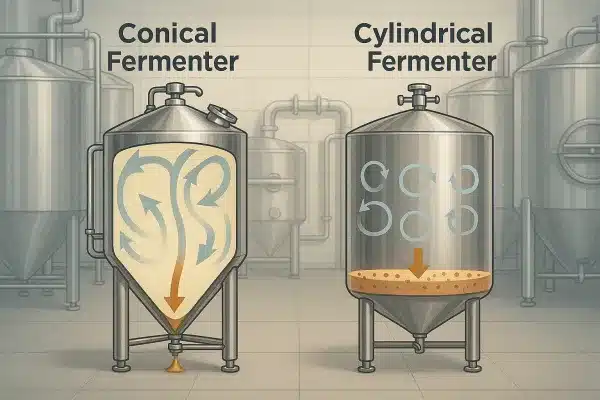

Conical vs. Cylindrical: Which Shape Wins?

원뿔형 발효기 create superior yeast circulation and efficient sedimentation, shortening fermentation times and enhancing beer clarity. By contrast, cylindrical vessels trap sediment over a broader surface, complicating yeast harvesting.

| 기하학 | Sediment Control | Yeast Harvest | Typical Use |

|---|---|---|---|

| 원뿔형 | ★★★★★ | One-pull bottom drain | Craft beer, kombucha |

| 원통형 | ★★☆☆☆ | Requires racking arm | Wine maturation, cold water mixing |

Which Stainless Steel Grade Is Best for Brewery Fermenters?

올바른 선택 스테인리스 스틸 is essential for durability, sanitation, and cost efficiency. The two common grades are 304 그리고 316L.

316L stainless steel is superior for breweries because it resists chlorides found in cleaning agents and hard water. Its low carbon content reduces corrosion risk at weld seams, and its molybdenum addition offers better pitting resistance.

304 스테인레스 스틸 is widely used due to its affordability and sufficient corrosion resistance under normal brewery conditions. Breweries with mild cleaning practices often find 304 stainless fermenters reliable and cost-effective.

| Grade | Chloride Resistance | Weld Ease | Cost Ratio |

|---|---|---|---|

| 304 | 양호 | ★★★★★ | 1.0 |

| 316L | 우수 | ★★★★☆ | 1.25 |

We offer hybrid designs: a 304 shell combined with a 316L cone for a perfect balance between performance and price.

Explore smart designs like our Commercial beer equipment for sale

What Size Fermenter Do You Need? Gallon-to-Barrel Ratios Explained

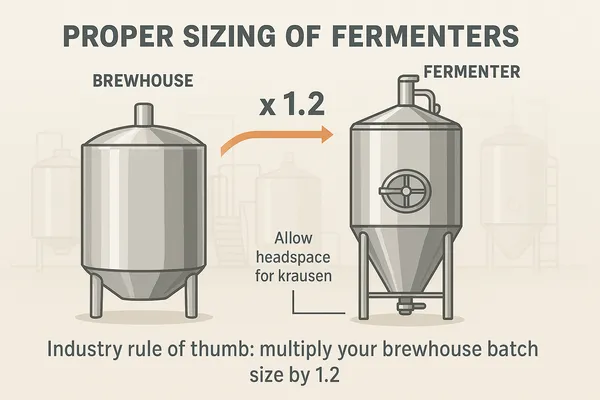

Sizing your fermenters correctly ensures efficient cellar management. The industry rule of thumb: multiply your brewhouse batch size by 1.2 to allow headspace for krausen.

| 양조장 | 발효기 용량 | Liters | Gallon |

|---|---|---|---|

| 3 BBL | 3.5 BBL | 410 L | 108 gal |

| 10 BBL | 12 BBL | 1400 L | 370 gal |

| 30 BBL | 36 BBL | 4300 L | 1135 gal |

Correct fermenter sizing avoids messy blow-offs and maximizes production yield.

Try new recipes using our 500L craft beer brewery System before scaling up!

Cooling Jackets & Thermal Control: Keeping Yeast Happy

Fermentation generates heat. Without cooling, temperatures rise, stressing yeast and risking off-flavors.

Our fermenters feature:

Dimpled glycol jackets for efficient heat exchange.

Polyurethane foam insulation to minimize ambient heat intrusion.

Digital PLC controllers for precise ±0.2 °C temperature regulation.

Why Thermal Stability Matters

Reduces diacetyl rest time by 20 %.

Improves attenuation to 82 % efficiency.

Provides consistent fermentation timelines.

Some models offer dual-zone jackets for independent control over cone and cylinder—ideal for specialty brewing like kombucha. See our 콤부차 발효 탱크 for reference.

Sanitary Design: Valves, CIP, and Easy to Clean Surfaces

Hygiene is non-negotiable. Every fermenter features:

Tri-clamp sanitary fittings to prevent contamination.

CIP(클린 인 플레이스) 시스템 with 360° spray balls.

Bottom drain valves for effective trub removal.

Internal surfaces polished to ≤0.4 µm Ra prevent microbial adhesion and simplify cleaning. This reduces cleaning time by up to 67 %, improves consistency, and maximizes production uptime.

Which Accessories Turn a Fermenter into a Profit Engine?

Upgrading your fermenter with smart accessories maximizes flexibility and ROI.

Must-Have Attachments:

회전식 랙 암: Pull crystal-clear beer from above sediment.

샘플 밸브: Easy, sanitary beer sampling.

Pressure relief/spunding valve: Manage internal pressure safely during fermentation.

Optional Upgrades:

Inline carbonation stone: Carbonate beer directly in the fermenter.

Thermal blanket: Boost insulation for tanks exposed to temperature swings.

Caster wheels or mobile rack stands: Move fermenters easily within your brewery.

Explore options in our beer equipment kits to customize your equipment for growth.

Real-World Comparison of Brewery Tanks—A Craft Beer Case Study

A Taproom upgraded from plastic fermenters to our stainless steel conical models. The impact was immediate:

| KPI | Before (Plastic) | After (Stainless) | Improvement |

|---|---|---|---|

| Batch loss | 8 % | 2 % | +6 % yield |

| Contamination incidents | 3/year | 0 | Full elimination |

| Carbonation time | 48 h | 32 h | 33 % faster |

| Cleaning labor | 90 mins | 30 mins | 67 % reduction |

Their upgrade included our 1000L beer processing equipment.

Installation, Global Service, and Lifetime Technical Support

We’re a manufacturer, not a reseller—meaning full control from design to delivery.

Installation Process:

Crated fermenters arrive safely packaged.

Local team positions, levels, and connects glycol and drain systems.

Remote commissioning by our technical engineers ensures perfect startup.

우리의 이동식 컨테이너 양조장 solution offers instant brewing flexibility.

You’ll have lifetime technical support, manuals, remote troubleshooting, and priority spare parts availability.

Price, ROI, and Financing: When Does Premium Equipment Pay Off?

High-quality fermenters have slightly higher initial costs (~15-20 % more) but pay off through:

6 % higher efficiency from less beer loss.

30 % lower maintenance over 5 years.

70 % resale value even after a decade.

Flexible financing and deferred payment options help breweries invest without cash flow strain.

Book a demo to experience the quality beer equipment.

자주 묻는 질문

How long does a stainless steel fermenter last?

: With proper CIP and maintenance, more than 25 years.

Do I need a separate brite tank?

: Not necessarily. Many fermenters double as unitanks, though brite tanks improve clarity for packaged beer.

Can I ferment other beverages like cider or wine?

: Yes. Proper cleaning allows use across beer, cider, wine, and distilling.

What’s the delivery time to Europe?

: Typically 35–45 days including customs clearance.

Is a 60-degree cone necessary?

: Yes, it promotes efficient sediment removal and yeast harvesting.

주요 내용

Stainless steel fermenters are vital for consistent, high-quality beer production.

Conical bottoms and precision cooling jackets create the optimal fermentation environment.

Properly sized fermenters with 20 % headspace ensure smooth krausen management.

Smart accessories amplify your fermenter’s value and operational efficiency.

Choosing a reliable manufacturer with full service support protects your investment.

Contact our team to explore customized brewing solutions and unlock your brewing potential—batch after batch!