As an important place for beer production, the maintenance of the brewery’s production equipment, environment, and processes is directly related to production efficiency, beer quality, and factory safety. Beer production involves multiple links, from raw material processing and fermentation to packaging. Each link requires meticulous management and effective maintenance. With the continuous expansion of the production scale, the daily maintenance of brewery equipment and facilities is particularly important.

Why is it important to maintain a brewery?

Ensure beer quality

Beer quality requirements are very high. Factors such as the selection of raw materials, fermentation process, and storage temperature will affect the taste and quality of the final product. Equipment maintenance is not only to prevent failures but also to ensure that every link in the production process can proceed stably. For example, temperature control systems, filtration equipment, and piping systems all need to be carefully maintained to avoid contamination or affecting the beer flavor.

Reduce maintenance costs

When equipment fails, the maintenance cost is often high, especially for some key equipment, which requires a lot of time and money to repair. If potential problems can be discovered and solved in time through regular maintenance, sudden failures can often be avoided and maintenance costs can be reduced.

Enhance safety

The production process of a brewery often involves high temperature, high pressure, and chemical reactions, so safety issues are particularly important. Aging or failure of equipment may lead to safety accidents. Therefore, regular equipment inspection and maintenance can effectively improve the safety of the plant and prevent safety accidents.

Common maintenance problems in breweries

Equipment aging and failure

As the use time increases, the equipment in the brewery will gradually age. In particular, some high-load equipment, such as fermentation tanks, filters, refrigeration equipment, etc., are prone to failure. Equipment failure will not only lead to production interruptions, but also may affect product quality, so it is necessary to regularly inspect the equipment and replace wearing parts.

Pollution and odor problems

Bacterial contamination and odor problems may occur during the production of beer, especially in the fermentation stage. If the equipment is not cleaned and maintained in time, pollutants may enter the production process and affect the taste and quality of the beer. For example, water pollution in the cooling system and sediments in the pipeline may cause these problems.

Unstable temperature control

The fermentation process of beer is very sensitive to temperature. Failure or instability of the temperature control system may lead to an incomplete or abnormal fermentation process, thereby affecting the taste and alcohol concentration of beer. Maintaining temperature control equipment and ensuring the stability of fermentation and storage temperature is one of the key tasks of brewery maintenance.

Failure of automated control system

Most modern breweries rely on automated control systems to manage the production process. Failure of the automation system may cause problems in various aspects of production, such as inaccurate raw material feeding, uneven fermentation, packaging errors, etc. Such failures usually require professional diagnosis and repair.

Loss of accessories and materials

Brewery equipment involves a large number of accessories and materials, such as pipes, valves, filters, etc. The aging, damage, or wear of these accessories and materials will affect production efficiency and equipment safety. Therefore, regular inspection and replacement of these vulnerable accessories is a necessary part of daily maintenance.

How to maintain a brewery?

Regular equipment inspection and preventive maintenance

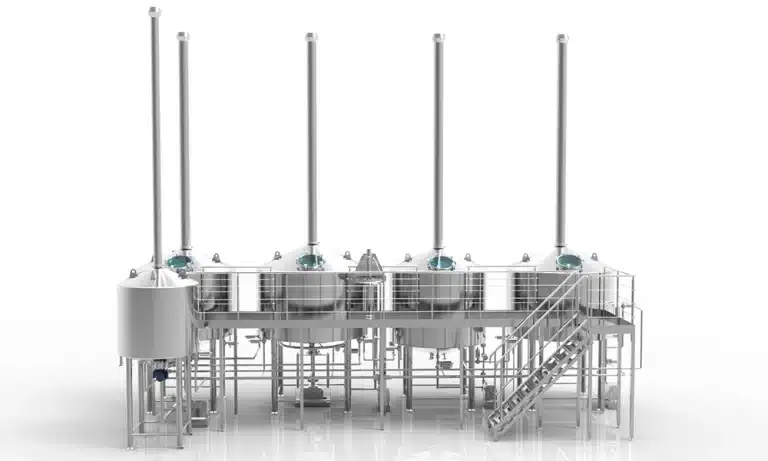

The equipment in a brewery is the core of the production process, including brewing systems, fermentation tanks, filters, cooling systems, packaging equipment, etc. These equipment are prone to wear and aging under long-term high-load operation. Therefore, regular inspections are the key to preventing equipment failures. Preventive maintenance measures usually include lubrication, cleaning, and replacement of vulnerable parts of the equipment. For example, regularly check the temperature control system of the fermentation tank to ensure accurate temperature control; check the pipeline system to avoid flow problems caused by scale accumulation. In addition, replacing parts with large wear and tear, such as seals and valves, is also part of daily maintenance, which can effectively avoid sudden failures affecting production.

Ensure equipment cleanliness and hygiene.

In the process of beer production, cleanliness, and hygiene are crucial. Contamination of equipment and pipelines will not only affect the taste of beer but may also cause bacterial growth and cause beer deterioration. Regular cleaning of all equipment that comes into contact with raw materials, yeast, and finished beer is basic maintenance work. To ensure the cleaning effect, many breweries use automatic cleaning (CIP) systems to thoroughly clean brewing and fermentation equipment. During the cleaning process, the cleaning agents and disinfectants used must meet food safety standards to prevent residues from affecting the quality of beer.

Maintenance of temperature control system

The temperature control system is crucial in breweries, especially during fermentation and storage. Even slight changes in fermentation temperature can have a significant impact on the flavor and alcohol concentration of beer. Therefore, regular inspection and calibration of the temperature control system is a key maintenance task. Check the sensors, heating, and cooling systems of the temperature control equipment to ensure their accuracy and stability. At the same time, the system’s pipes and coolants also need to be replaced or cleaned regularly to avoid inaccurate temperature control due to aging equipment, which affects the production process.

Maintenance of automation equipment and systems

Most modern breweries use automation equipment and information management systems to improve production efficiency and accuracy. Automation equipment such as automatic packaging machines, filling machines, brewing control systems, etc. require regular maintenance. To ensure the stable operation of these systems, the factory should be equipped with professional automation technicians to troubleshoot and update the system. In addition, the automation system also needs to regularly back up data and perform software upgrades to prevent system vulnerabilities or data loss from affecting production. Real-time monitoring and alarm systems are powerful tools to ensure production safety and can provide timely warnings when equipment is abnormal.

Replace vulnerable parts in time.

During the long-term use of brewery equipment, some accessories such as pipes, filters, valves, etc. are prone to wear or aging. Regular inspection of these vulnerable parts and timely replacement are the key to ensuring the normal operation of the equipment. When replacing accessories, high-quality original accessories should be used to ensure the long-term stability of the equipment. Especially for key equipment involving raw material processing and fermentation, choosing high-quality accessories can greatly reduce the probability of failure.

Maintaining the plant environment and safety

The environmental sanitation and safety facilities of the brewery also need regular maintenance. Good ventilation, lighting temperature, and humidity control should be maintained in the plant. The work area should be kept clean and tidy to avoid accumulation of debris and prevent fire and other safety hazards. At the same time, the integrity of the fire-fighting equipment, emergency evacuation passages, and safety warning signs in the factory should be checked regularly. For areas where hazardous chemicals are used, their storage and use status needs to be checked regularly to ensure compliance with safety regulations.

Equipment training and technical support

To improve the equipment maintenance level of the brewery, the operators and maintenance technicians in the factory should receive regular equipment training. Operators should understand the basic working principles of the equipment and common troubleshooting methods so that they can solve minor problems in time. Maintenance personnel need to regularly update equipment and conduct technical training to master the latest maintenance skills and equipment maintenance methods. In addition, breweries should also establish complete equipment archives and maintenance records to ensure that the maintenance history of each equipment can be traced back, to facilitate the analysis of the cause of the failure and optimize the maintenance strategy.

Optimization and improvement of production processes

The maintenance of equipment is not only limited to the equipment itself but also involves the optimization of the entire production process. For example, through data analysis, the production process can be optimized, energy consumption can be reduced, and production efficiency can be improved. Optimizing the bottleneck links in the production process can extend the service life of the equipment and reduce failures caused by excessive use of certain equipment. Regularly reviewing and evaluating the production process and finding room for improvement are important guarantees for the long-term and stable operation of the brewery.

Implementing intelligent and digital management

With the development of science and technology, many breweries have begun to introduce intelligent and digital management systems. Through sensors, Internet of Things technology, and big data analysis, breweries can monitor equipment operating status, production parameters, energy consumption, and other information in real-time. This can not only detect equipment abnormalities in advance but also respond in time when failures occur to reduce downtime. At the same time, the intelligent system can provide accurate fault prediction and maintenance suggestions, helping maintenance personnel perform maintenance operations in a targeted manner and improve maintenance efficiency and accuracy.

Tips for maintaining brewing equipment

- If you do not use the brewing equipment temporarily, be sure to clean the equipment thoroughly. After the water flow is smooth, close the valve. In addition, before reusing the equipment after a long time, please clean the equipment thoroughly.

- The heat exchanger should be disassembled and cleaned after a long-term operation or long-term disuse. Do not use a metal brush when cleaning, do not bend, twist, step on, or squeeze the heat exchanger plate, and replace the sealing gasket in time if it is aging.

- Regularly check the motor and pump connection and grounding to ensure the correct connection. Check the oil level of the reduction motor and hydraulic device, and add lubricating oil regularly according to the instructions. Regularly check the tightness of the mixing and tillage accessories. All pumps in use must not run idle or reverse. If leakage is found, the pump seal should be replaced in time.

- Regularly check whether there are foreign objects and impurities in the mill hopper, check whether the mill fasteners are loose, the tightness of the mill drive belt, and the reliability of the safety protection device. Clean the mill roller regularly.

- Regularly check the pressure gauge and safety valve of the steam heating equipment to ensure that the steam trap is unobstructed; heating shall not be started if the specified temperature is not reached. Warning signs should be hung above high-temperature pipes such as steam and wort and mashequipment during operation to prevent burns.

- When filtering, do not extract wort at a high flow rate to damage the sieve plate! When the equipment is not in use, do not place heavy objects on the sieve plate to prevent the sieve plate from deforming. Keep all mechanical parts running smoothly during operation.

- Check the plate heat exchanger for leaks, liquid leakage, and fluid flow at any time, and repair them immediately if any.

Tips for maintaining fermentation tanks

- If there is a leak at the inlet pipe and outlet pipe joints, tightening the joints cannot solve the problem, add or replace the packing.

- The pressure gauge and safety valve should be checked regularly, and the fault should be replaced or repaired in time.

- When cleaning the fermentation tank, please use a soft brush to scrub it, and do not scratch it with hard objects to avoid damaging the surface of the fermentation tank.

- The matching instrument should be calibrated once a year to ensure normal use.

- Electrical equipment, instruments, sensors, and other electrical equipment are strictly prohibited from direct contact with water and steam to avoid moisture.

- When the equipment is not in use, it should be cleaned in time, and the remaining water in the fermentation tank and each pipe should be drained; loosen the fermentation tank cover and hand hole screws to avoid deformation of the sealing ring.

- If the fermentation tank is not in use temporarily, it is necessary to empty the fermentation tank and drain the remaining water in the tank and each pipe.

Summary

The maintenance of a brewery is not only to keep the equipment running well but also to ensure the efficiency of the production process and the quality of the beer. Through regular inspections, preventive maintenance, monitoring, and other means, the service life of the equipment can be maximized, production costs can be reduced, and the quality and safety of beer can be guaranteed.