Starting a craft brewery is a long and complicated process. Once you find a suitable location, the first order of business is to create a brewery floor plan. Creating a brewery floor plan involves more than bringing in equipment and fitting it into place. Instead, your floor plan needs to be considered based on a variety of factors. Micet group designers will tell you on the best layout for your brewery.

A brewery floor plan for what?

A floor plan is a map of the entire physical space of a brewery. Every inch of space in a building should be considered. The floor plan is a visualization of the completed brewery and will guide the layout of the physical space. They are also required for building permits in many states.

Floor plans must a little creativity and research. How your guests and servers navigate your brewery is as important as the ambiance and experience.

The brewery floor plan includes:

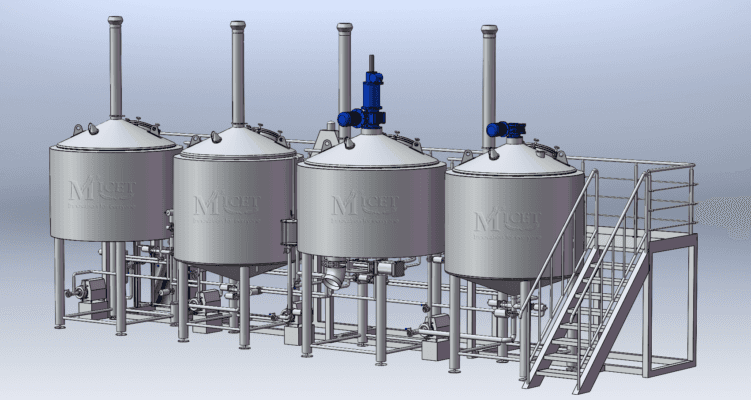

- Your brewery equipment and brewing area

- Brewery kitchen and kitchen equipment

- Bar area

- Lounging and dining areas

- Preparation area

- Storage area

- Seating and waiting areas

- Office and staff area

- Bathroom

- Wait

When creating this project, it was important to consider how the floor plan would affect the brewing process, receiving inventory, and serving customers. These different operations need to work together , as dictated by your footprint.

Considerations for Brewery Floor Plans

There are many factors to consider when designing a brewery floor plan. To ensure the success of your brewery, it is important to consider the layout of your facility.

Water supply

Water is a critical component of the brewing process, and a reliable water supply is vital to any brewery. When designing your brewery floor plan, consider water supply location and pipe routing.

Electricity supply

Electricity is another key component of the brewing process, and you should consider the location of electrical panels and routing of electrical wires to ensure your equipment has the power it needs to operate .

Grain bucket

Grain kegs are an important part of the brewing process, and it’s important to make sure they’re in a convenient location within the brewery. You should consider the size of your grain bin and make sure it can accommodate the amount of grain required for your brewing operation.

Packaging and labeling area

The packaging and labeling area is where your beer is packaged and labeled for distribution. When designing your brewery floor plan, consider the location of packaging and labeling areas and the routing of your beer production lines. You should also consider the size of your packaging and labeling area and make sure it can accommodate your production volumes.

Drainage system

Drainage is a key component of any brewery floor plan. You should consider the slope of your floor and make sure your drainage system is designed to operate on that slope. You should also consider the location of your drain pipes and make sure they are easy to clean and maintain.

Things to consider when designing a brewery floor plan

Improve cleanliness

While your brewery layout is in the design phase, build an easy-to-clean brewhouse ahead of time. Non-porous epoxy can be used when using flooring, which has an antimicrobial layer on the surface that requires less chemical scrubbing and is easy to clean. Will save you time, money and improve the quality of your beer.

Improve energy efficiency

Energy conservation considerations are a cost-saving measure for craft breweries. A good and proper craft brewery layout can play a very critical role in saving energy. Effective energy conservation measures will reduce the brewery’s long-term costs.

Improve cost savings

By planning for extra space ahead of time, you can take steps in your design and production to save on brewery equipment layout costs. When a brewery’s capacity cannot meet demand, more equipment such as fermenters is purchased to increase production. Store lauter tun drains in the brewhouse area and discard them for later brewing and reduce water costs. By installing equipment to collect beer spills from the bottling area, you can also recycle used beer and save costs.

Cost reduction measures

brewery equipment

Investing in quality equipment can save you money. High-quality equipment is less likely to break down, which can save money on repairs and replacements.

Place

Choosing the right location for your brewery can also save you money. Find a location that is affordable and accessible.

Production Process

Optimizing production processes can also reduce costs. By reducing waste and optimizing workflow, you can save on raw material and labor costs. Also, consider using sourced ingredients to save on shipping costs.

Executive Brewery Floor Plan

Once you’ve developed a detailed blueprint and floor plan of your brewery, it’s time to start turning your plans into reality. Careful planning of your brewery layout is crucial. Your floor plan plays a vital role in the success of your business. If you leave out important considerations when planning, it could impact your operations or customer experience. Keep the above considerations in mind when planning your brewery layout. This will help you create a brewery that looks great, functions well, and provides a seamless customer experience.