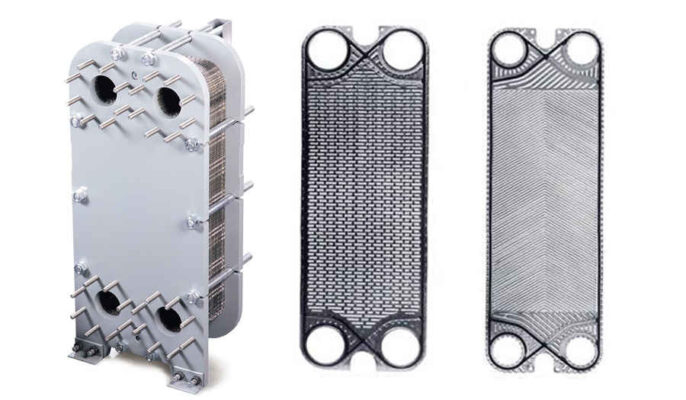

Heat exchangers are an important part of beer brewing systems. It is used to transfer heat from one fluid or gas to another, enabling efficient energy transfer and temperature control. Thus, cleaning and maintenance of the heat exchanger is very important to keep the system running . Regular maintenance keeps equipment in working order and helps prevent emergency repairs.

Why do heat exchangers need maintenance?

As the flow becomes more restricted, the heat exchanger will lose efficiency and reduce heat exchange. Also to restricting flow, the buildup of deposits on heat transfer surfaces can also reduce the heat transfer capacity of a heat exchanger.

Heat exchangers must maintenance to keep them running . Fouling, corrosion, or other damage can reduce heat exchanger performance. Maintenance also helps prevent emergency repairs from causing downtime.

Degraded heat exchanger performance results in increased operating and energy costs. As the system is under increasing stress, the following may occur :

- Performance drops generally

- random deviations from operating temperature or operating requirements

- Internal and external leakage

- Interference in the process

- Increased capacity requirements

- high energy consumption

The Importance of Heat Exchanger Cleaning and Maintenance

To ensure safe and smooth brewing, must to rank heat exchanger cleaning and maintenance.

The main reasons are as follows:

- Improve efficiency

- Extended service life

- Improve security

- Regulatory Compliance

- maintain peak performance

How to clean the heat exchanger ?

You can tell when the heat exchanger needs to be cleaned when it is not reaching the correct product temperature for heating or cooling. Incorrect temperatures are caused by fouling on the plate surface, which reduces temperature transfer.

Pressure drops higher than specified may be seen as fouling restricts passage and increases fluid velocity.

CIP cleaning

CIP equipment can clean the plate heat exchanger without . CIP provides chemical and mechanical cleaning for heat exchangers. If the system configuration prohibits CIP, the operator must perform manual cleaning. CIP cleans lime deposits on heat exchanger surfaces and passivates the surfaces to reduce corrosion susceptibility. Neutralize cleaning chemicals before draining.

Basic Chemical Cleaning Process

CIP chemical cleaning has the following advantages:

- Faster cleaning process

- Low labor intensity

- Clean parts that cannot be cleaned by mechanical cleaning

During the CIP chemical cleaning process, the operator generally follows four steps:

- Alkaline Cleaning: Removes buildup of organic matter.

- Rinse: Usually done with a high flow water rinser to remove loose debris and remaining residue from the alkaline step.

- Pickling: Helps to dissolve and soften dirt substances at a deeper level.

- Final rinse.

When should the heat exchanger be cleaned?

Heat exchanger inspections should be performed at least once a year, with more frequent inspections recommended for heat exchangers in dirty or corrosive environments.

The frequency of heat exchanger cleaning and maintenance depends on several factors:

- Types of heat exchangers: Different types of heat exchangers have different cleaning and maintenance requirements. For example, shell and tube heat exchangers may must more frequent cleaning than plate heat exchangers.

- Operating conditions: The operating conditions of the heat exchanger, such as temperature, pressure and fluid flow rate, will affect the rate of dirt and debris accumulation and the need for cleaning.

- Environmental conditions: The environment in which the heat exchanger operates (such as the presence of corrosive or abrasive substances) may affect the need for cleaning and maintenance.

- Industry Regulations: Some industries have regulations and standards that dictate the frequency of heat exchanger cleaning and maintenance.

How to tell if a heat exchanger needs repair?

Two Common Problems: Leakage and Slow Performance

Dirt and corrosion can both lead to reduced performance. Whether due to dirt or corrosion by-products, internal or external surfaces can become clogged, causing overheating. It also insulates the pipes, reducing the efficiency of heat transfer. If your heat exchanger is showing signs of performance degradation or leaking, it’s best to have it checked by an expert to avoid more serious problems.

How Often Are Heat Exchangers Maintained?

A heat exchanger should be serviced every 6 months to 4 years, depending on its environment. Standard heat exchanger maintenance or repair activities take a week or two. But, larger installations or more complex repairs will take longer.

Extra maintenance

Regular maintenance will keep the heat exchanger in good working order and allow for more efficient opening and closing.

- Keep the load rod and guide rod clean with paraffin oil.

- Keep fastening bolts clean for easy opening, closing, and change of dimension A.

- Lubricate the threads of the fastening bolts with EP (Extreme Pressure) grease.

- Lubricate the suspension wheels on the pressure plate and connecting plate.