Heat exchangers work by using “heat exchange” or “energy exchange” by using a series of “plates” or “tubes” (depending on the type of heat exchanger) to heat or cool a liquid. The liquid is separated by plates (in a plate heat exchanger) or tubes (in a tube heat exchanger); in a brewery, the pipes carry beer or cider product (such as wort) on one side and water on the other or refrigerant.

Plate heat exchangers are used in the brewing industry for heat transfer between two fluids. A heat exchanger is the best way to heat or cool any liquid to a precise temperature. As we test the role of heat exchangers in breweries, you’ll see that they will soon become an integral part of any brewing operation. This article will discuss the working principle of a plate heat exchanger used in brewing equipment.

What is a plate heat exchanger?

Plate heat exchangers are used to transfer thermal energy from one fluid to another. These fluids never meet because they are separated by the heat exchanger. a plate heat exchanger consists of many parallel plates stacked on top of each other, creating channels through which fluid can flow. The spacing between the two opposing plates provides channels for fluid to flow through.

How is a plate heat exchanger constructed?

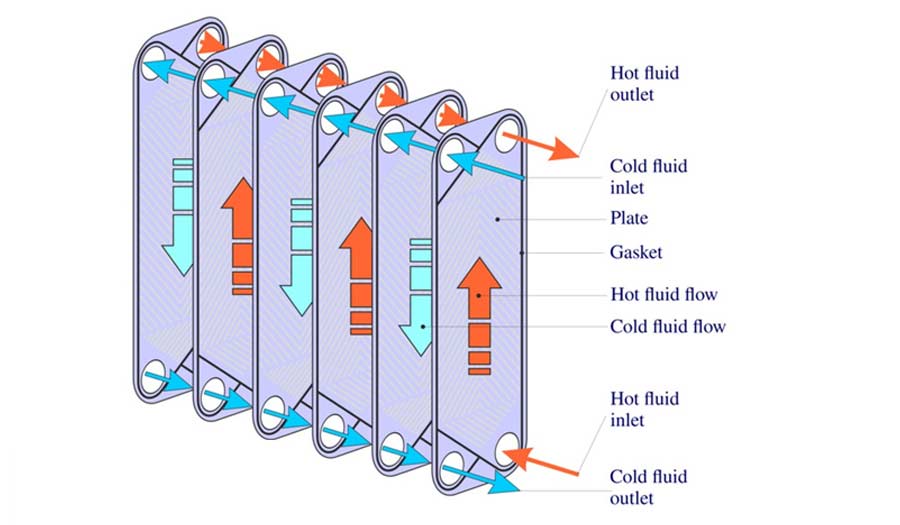

A heat exchanger consists of a series of parallel plates placed one on top of the other so on form a series of channels for fluid to flow between them. The spaces between two adjacent plates form channels for fluid flow.

Inlet and outlet holes in the corners of the plates allow hot and cold fluids to pass through alternating channels in the heat exchanger, so the plates are always in contact with hot fluid on one side and cold fluid on the other.

The size of the plates varies from a few square centimeters to flow. The number of plates in a single heat exchanger varies from ten to several hundred, thus achieving a surface exchange area of thousands of square meters.

What is the working principle of a plate heat exchanger?

The working principle of a plate heat exchanger is based on the countercurrent flow of two fluids. In the brewing industry, one liquid is usually wort, which is the liquid extracted from the crushing process, and the other liquid is usually cold water or glycol. During brewing, the wort is cooled to the desired temperature with cold water or glycol.

During brewing, the wort is cooled to the desired temperature with cold water or glycol. The plate heat exchanger consists of two main channels, one for the wort and the other for the cooling liquid. The two channels are separated by a thin metal plate, which is designed to maximize the heat transfer capability between the two fluids.

The wort flows through the channels on one side of the plate, while the cooling fluid flows through the channels on the other side of the plate. The two fluids flow in opposite directions, with the wort flowing from the inlet to the outlet of the plate heat exchanger and the cooling fluid flowing from the outlet to the inlet. As the two fluids flow in opposite directions, heat is transferred between them through the thin metal plates. The wort gives off heat to the cooling liquid, which absorbs the heat and carries it away.

In a plate heat exchanger, the flow is diagonal. While hot liquid enters at the top and exits at the bottom, cold liquid enters at the bottom and exits at the top. So, the efficiency reaches the highest level.

Different Types of Plate Heat Exchangers

- Brazed Plate Heat Exchangers: For Refrigeration and Industrial Applications

- Gasketed Plate Heat Exchangers: Suitable for many industries such as HVAC, food, brewing, and pharmaceuticals.

- Welded plate heat exchangers: used in the oil, gas, and chemical industries.

- Semi-welded plate heat exchanger: Combines the use of welded and gasketed plates. The heat exchanger consists of two sets of plates welded together.

Advantages of plate heat exchangers

- Efficiency: Plate heat exchangers transfer heat between two fluids, making them ideal for the brewing industry, where precise temperature control is critical.

- Compact size: The plate heat exchanger is compact and easy to install and use in brewing equipment.

- Ease of Cleaning: The design of the plate heat exchanger allows for easy cleaning which is important in the brewing industry as cleanliness is critical to maintaining the quality of the product.

- Cost-effective: Plate heat exchangers are cost-effective to operate, making them a popular choice for small and medium-sized breweries.

The most suitable heat exchanger for breweries

So what heat exchanger is best? It depends on several factors.

Several different types of heat exchangers may be suitable, but the most suitable for breweries are plate heat exchangers or tube heat exchangers.

One of the considerations for using heat exchangers in breweries is that beverages often contain a lot of sediment. With things like yeast, wort, barley grains and other sediments, heat exchangers are likely to develop deposits that will clog the heat exchanger – but both plate and tube heat exchangers can be maintained, cleaned and provided The service runs.

Plate heat exchanger

Plate heat exchangers are suitable for breweries. Brewers can take steps to reduce settling, such as swirling the mix and letting anything settle before processing, or taking care not to bump any ingredients before pumping. Repairs to plate heat exchangers are also easier as they can be taken apart without much space – whereas shell and tube heat exchangers need more space to repair.

Tube Heat Exchanger

Many brewers may prefer tube heat exchangers, which are less likely to become clogged with sediment. In fact, tube heat exchangers are designed to handle liquids that contain a lot of sediment (such as beer), so there is little risk of plugging a shell and tube heat exchanger. They are also easy to clean in place, as you can remove the valve caps at both ends, brush the tubes and spray them out before reassembling the heat exchanger. For many, this may be their first choice. There is no risk of shell and tube heat exchanger clogging.

Material

Another consideration is what material is best for your needs: titanium plate or stainless steel? The engineer who selects the heat exchanger with you will be able to tell you what might better suit your needs.