If you want to make delicious wine, it is essential to have the right distillation equipment. Whether they are a beginner or a master in the winemaking industry, having the right distillation equipment allows them to maximize the potential of their products. Distillation begins with the fermentation of liquid, such as liquid alcohol such as mash or wine, being heated in a distiller. As the liquid heats, the alcohol evaporates and rises to the top of the distiller, where it is collected and concentrated into a highly concentrated solution. This article will give you a detailed introduction to how to use distillation equipment for winemaking, including equipment selection and other content.

What is distilled wine?

Distilled wine is wine that has been processed to increase the alcohol content. The alcohol in wine is produced through fermentation. Wine grapes are crushed to extract the juice, which winemakers call must. The grape juice contains sugars, which are converted into alcohol when yeast is added.

When the alcohol content is too high, yeast cannot survive, which naturally limits the concentration of fermented wine. This is why you can’t find regular wine with an alcohol content of more than 16%. To make a beverage with a higher alcohol content, the wine must be distilled.

Basic principles of distillation equipment

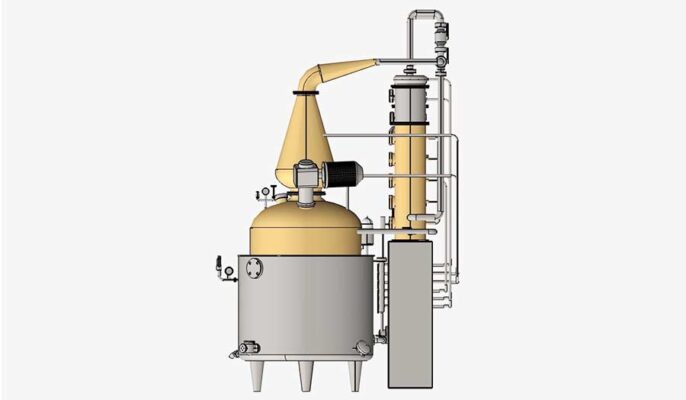

Distillation is a process of separating different components in a liquid mixture based on the different boiling points of each element. Distillation equipment separates alcohol and other components by heating the liquid to turn it into steam and then condensing it into liquid. Common distillation equipment includes a distiller (such as the common copper distiller), tower distillation equipment, and reflux distillation equipment.

- Heating pot: used to heat the fermentation liquid to promote its evaporation.

- Steam generator: directs the steam generated by heating to the condensing device.

- Condenser: cools the steam into liquid, using cooling water or air cooling system.

- Receiving container: used to collect the distilled liquid.

Distillation and Brewing Process

- Selection of Raw Materials: Depending on the type of target alcohol, appropriate raw materials are selected, such as grains (barley, corn, rye), fruits (grapes, apples), molasses, etc.

- Fermentation: Mix the raw materials with water to make a fermentation liquid. Yeast is added to the fermentation liquid, and the yeast converts sugars into alcohol and carbon dioxide. Different yeast strains have different effects on the fermentation process and the final flavor.

- Distillation: Pour the fermented liquid into a distillation pot and heat it to evaporate the alcohol and other volatile components. The evaporated alcohol vapor is cooled by a condenser and recondensed into a liquid, which is the distilled liquid.

- Aging: Under specific temperature and humidity conditions, the alcohol liquid reacts chemically with the material in the container (such as oak) to produce complex flavors and aromas.

- Blending and Filtration: Different batches of distilled liquor are blended to ensure consistency of flavor. Residual solids and impurities are removed by filtration to improve the purity and taste of the alcohol.

- Packaging: The final product is bottled, labeled and sealed, ready for sale. Quality inspection is performed before packaging to ensure compliance with standards.

Types of Distillation Processes

- Fractional distillation: This process involves distilling the same liquid multiple times. Distillation is performed multiple times at increasing temperatures to remove different substances from the mixture.

- Steam distillation: Distillation is performed to extract all elements from temperature-sensitive compounds. The implementation of this process requires subjecting the liquid to different boiling temperatures.

- Vacuum distillation: Some substances present in the liquid have extremely high boiling points. In this case, it is more efficient to reduce the tower pressure. This way, elements in the mixture with much lower vapor pressure may evaporate more easily.

Distilling equipment required for the brewing process

- Wort barrel: This container mixes malt with water at a controlled temperature, converting starch into fermentable sugars through mashing, thereby starting the wort fermentation process. The container is equipped with a false bottom and sieves to separate the spent grains from the liquid, producing wort ready for fermentation.

- Fermentation tank: The fermentation tank is key to converting sugars into alcohol and is used to store wort to which yeast is added. Temperature control is essential during the fermentation process, which can last for several days. The fermentation tank is equipped with a pressure release valve to help continuously release the gases produced during the fermentation process.

- Pumps: While small breweries can be managed manually, large breweries rely on pumps to move liquids safely and efficiently. A typical setup may include a wort pump and a high-concentration pump to simplify operation.

- Pot still: Pot stills are similar to large kettles and are ideal for producing strong-flavored spirits such as tequila or single malt whiskey. They require regular downtime for cleaning and refilling, and have limited efficiency, but provide unique flavors.

- Column stills: These stills consist of columns and vertical plates that allow for continuous distillation, and are suitable for lighter spirits such as vodka, rum, and gin. While they lack the flavor imparted by pot stills, they are more efficient.

- Condensers: Coils that cool and condense the evaporated alcohol, condensers help collect the concentrated alcohol. Often, the product undergoes additional distillations to further concentrate it.

- Filtration equipment: Various options such as bag filters, filter cartridges, or filter paper help remove particulate matter and clarify the alcohol before storage, thereby improving its quality and appearance.

- Storage and aging vessels: Stainless steel tanks and oak barrels are common choices for storing distilled spirits, allowing them to mature and develop flavor before bottling.

- Clean and safe equipment: Maintaining cleanliness and ensuring safety are top priorities in distillery operations. Adequate sanitation and safety measures equipment are essential to safeguard product quality and worker health.

How to choose distilling equipment?

Types of distilling equipment

There are many types of commercial alcohol distilling equipment, each of which serves a different purpose in the distillation process. There are three main types: pot stills, column stills, and hybrid stills. Pot stills are known for their traditional and handcrafted craftsmanship, which are ideal for small batches. On the other hand, column stills are more suitable for large-scale production due to their continuous distillation process. Hybrid stills strike a balance between the two, combining elements of pot stills and column stills for versatility.

Capacity and size

Determining the right size and capacity of distilling equipment is essential to optimizing production. Before making a decision, consider your production goals, expected demand, and available space. Investing in equipment that meets your production needs and is not over- or under-utilized is essential for cost-effectiveness.

Material quality and construction

The quality of the materials used in commercial distilling equipment has a significant impact on its performance and lifespan. Stainless steel is a common choice due to its durability, corrosion resistance, and easy cleaning. High-grade copper parts can also enhance the flavor of certain spirits, such as whiskey.

Heating Methods and Temperature Control

Efficient and precise heating is essential to achieve the desired alcohol strength and flavor profile. Heating methods vary, from direct fire heating to steam or electric heating. Each method has its advantages and affects the characteristics of the final spirit. In addition, complex temperature control mechanisms are essential to maintain consistency during the distillation process.

Safety and Compliance

Distilling alcohol involves potentially dangerous processes, so safety is a top priority. When purchasing commercial distillation equipment, make sure it meets safety standards and regulations. Complying with local and international regulations is essential to avoid legal issues and ensure the well-being of operators and consumers.

FAQ

How to prepare raw materials?

Select the appropriate raw materials (such as grains, fruits, or molasses) and perform the necessary processing. For example, crush the grains and saccharify them, or press the fruits into juice. Make sure the raw materials are clean and meet the requirements of winemaking.

How do you set up the distillation equipment?

Pour the fermented liquid into the still and heat it to evaporate the alcohol. The vapor is cooled and converted into liquid through the condenser. Set the appropriate heating temperature and condensation conditions to ensure that the distillation process proceeds smoothly.

How to deal with foam during the distillation process?

Add foam inhibitors or use foam breakers to prevent foam from overflowing and affecting the distillation effect. Ensure that the liquid level of the still is appropriate to avoid excessive foam generation.

How to ensure distillation efficiency?

Regularly check the status of the fractionation tower, condenser, and other components to keep them clean and in good working condition. Adjust the reflux ratio and heating parameters of the fractionation tower to optimize the separation effect.

How to clean and maintain the equipment?

Follow the equipment manufacturer’s cleaning and maintenance guidelines and regularly clean the still, condenser, and other key components. Regularly check the function of the equipment to ensure that all parts are functioning properly.