Struggling with inconsistent batches, contamination risks, or equipment that just doesn’t last? Inferior míchací nádrže can lead to wasted ingredients, production delays, and ultimately, a compromised final product, hurting your brand and bottom line. Imagine achieving perfect homogeneity every time with durable, sanitární tanky built specifically for your needs.

Stainless steel mixing tanks are essential for quality mixing and storage because they offer superior durability, excellent odolnost proti korozi, and are inherently sanitární, preventing contamination. Their non-reactive surface ensures product purity, crucial in industries like potraviny a nápoje, pharmaceuticala chemické zpracování. High-quality stainless steel mixing provides reliability and longevity, safeguarding your production process and ensuring consistent product quality in every nádrž.

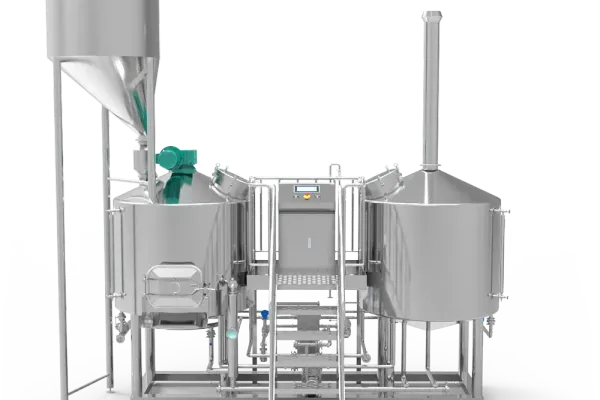

Jako Výrobní závod pivovarského zařízení, we’ve seen firsthand how the right nádrž transforms production. We work daily with passionate creators: Startup Craft Brewery Owners carefully crafting their first batches, Experienced Brewmasters demanding precision, Brewpub & Restaurant Chains ensuring consistency across locations, and innovative Beverage Entrepreneurs venturing into kombucha or even high-quality distillery equipment. They all share a common need: reliable, vysoce kvalitnía customizable solutions. It’s not just about a nádrž; it’s about the heart of their operation. This critical piece of zpracovatelské zařízení is where magic happens – ingredients combine, flavors meld, and quality takes shape within the nádrž.

Choosing the perfect míchací nádrž can feel overwhelming. You’re looking at different grades of stainless steel, maybe a bunda pro regulace teploty, various agitator designs, specific gallon capacities, and countless custom features. It’s a big decision! This guide is here to help. We’ll dive deep into the world of stainless steel mixing tanks, sharing insights from our years of experience crafting these essential tanky for clients ranging from wineries and cider producers to large-scale food processing facilities. We understand that you need more than just a nádrž; you need a dependable partner offering robust technická podpora. Let’s explore why stainless steel is the champion material and how you can select the ideal míchací nádrž for your unique mixing and storage tank applications. This exploration covers everything from simple skladovací nádrže to complex, jacketed míchací nádrže.

What Makes Stainless Steel the Gold Standard for Mixing Tanks?

Why stainless steel? It’s a question we hear often, and the answer is clear: it’s simply the best material for the job in most demanding applications. Grades like 304 nerezová ocel a 316l stainless steel are the workhorses of the industry, especially for míchací nádrže. The number one reason? Incredible odolnost proti korozi. Stainless steel has a secret weapon: chromium. This element forms a thin, invisible, and self-healing layer on the surface. Think of it like a protective shield for your nádrž. This shield stops rust and prevents the metal from reacting with whatever you put inside – whether it’s acidic beer, delicate pharmaceutical compounds, or ingredients for food processing. This non-reactivity is absolutely vital. It means your product stays pure, without picking up unwanted metallic tastes or contaminants from the nádrž itself.

But it’s not just about preventing rust. Stainless steel is tough. Really tough. These tanky boast impressive durability. They can handle the bumps and scrapes of a busy production floor, withstand high temperatures during cleaning or processing, and endure countless cycles without breaking down. What does this mean for you? A longer lifespan for your nádrž and a lower overall cost in the long run. We build our tanky from high-quality stainless steel because we know they need to be reliable workhorses for our clients, day in and day out. A stainless steel tank built well will serve you for years, minimizing expensive downtime. Plus, its smooth, non-porous surface makes it naturally sanitární and incredibly easy to clean – a huge benefit for any industry where hygiene is paramount. This makes stainless steel mixing the reliable choice. The strength allows for complex designs, including pressure-rated tanky (ASME compliant if needed) and various agitator mounts without issue.

How Do Different Types of Mixing Tanks Serve Various Industries?

While stainless steel forms the foundation, the actual design of the míchací nádrž tailors it for specific jobs across different industries. A craft brewery’s needs are worlds apart from a pharmaceutical lab’s requirements or a large food processing plant’s demands. Think about brewing: you often need precise regulace teploty. That means using jacketed tanks. These special tanky have an outer layer, a bunda, allowing glycol or steam to circulate for heating or cooling, crucial during mashing or fermentation. We often use a dimple jacket design for efficient heat exchange in brewery tanky. The broader food and beverage industry absolutely requires sanitární designs for their tanks for food. This means super smooth welds inside the nádrž, polished surfaces meeting specific standards (like 3-A), and carefully placed port connections to prevent any bacteria from hiding.

Now, consider chemické zpracování. They might need tanky made from 316l stainless steel because it offers even better odolnost proti korozi against harsh chemicals. These tanky might also need special seals or venting systems. The cosmetic industry often deals with thick lotions and creams, so their míchací nádrže need powerful agitator systems, sometimes with scrapers, to ensure everything blends evenly within the nádrž. As manufacturers, we produce various types z míchací nádrže – from basic skladovací nádrže used purely for holding liquids to complex, engineered vessels for specific reactions or blending. Understanding the unique challenges of each industry allows us to craft the perfect tank configuration, whether it needs a special cone bottom for complete draining, a specific slope, or convenient features like a hinged lid. It’s about providing the right type of tank for the job.

Understanding Agitators and Mixers: What’s Right for Your Process?

Okay, let’s talk about what happens inside na nádrž. Na stránkách . agitator nebo mixer (people use both terms) is the part that does the actual blending, stirring, dissolving, or keeping things moving. Choosing the right agitator is super important for getting your mixing process perfect. You need to think about: how thick is the liquid? Do you need a gentle swirl or a powerful vortex (agitace)? What’s the goal – just mixing, dissolving powders quickly, or keeping solids from settling in the nádrž?

There are several common types of agitators, each suited for different tasks inside the míchací nádrž:

- Propellers: Great for thin liquids, like stirring water or light solutions. They push the liquid straight down or up. You’ll find these in simpler blending tanky.

- Paddles: Good for gentler mixing of slightly thicker stuff. Breweries sometimes use these in mash konvice tanky.

- Turbines: These are versatile! They can create flow patterns going outwards and downwards/upwards. Good for general mixing, getting gas into liquids, or keeping solids suspended. Used a lot in chemické zpracování and some potraviny a nápoje tanky.

- Anchor/Gate Agitators: These look like they hug the inside walls of the nádrž. They’re designed for really thick, sticky products like creams or pastes. They scrape the walls to ensure everything mixes evenly and heat transfers well. Common in cosmetic or thick food production tanky.

- High Shear Mixers: Need to make emulsions (like mayonnaise), break down particles really small, or dissolve powders super fast? These are the powerhouses for that kind of industrial mixing.

As manufacturers who design complete tanks and mixer systems, we always ask detailed questions about your specific application. A startup brewery might just need a simple paddle agitator for their mash nádrž, but a pharmaceutical company might need a very specialized, super-sanitární high-shear mixer in their stainless steel mixing tank. Making sure the agitator works perfectly with the nádrž design (sometimes adding internal plates called baffles) is key to successful mixing. This ensures the míchací nádrž performs exactly as needed.

Jacketed Tanks vs. Single-Wall Tanks: When Do You Need Temperature Control?

One big decision when choosing a míchací nádrž is whether you need to control the temperature inside. This brings us to the difference between a single-wall nádrž a jacketed tank. A single-wall nádrž is just that – a single layer of stainless steel. It holds your product, but it doesn’t have a built-in way for heating or cooling. These tanky work fine if you’re just doing mixing and storage at room temperature, or if you plan to heat or cool the product před přechází do nádrž.

But many processes need precise regulace teploty. Think about brewing beer – you need specific temperatures for mashing, boiling, fermenting, and cooling. Zpracování potravin often involves cooking or pasteurizing right in the nádrž. This is where jacketed tanks shine. A bunda is like a second skin wrapped around the main nádrž, creating a space in between. You can pump a heating medium (like steam or hot water) or a cooling medium (like glycol or cold water) through this space. The heat (or cold) transfers through the nádrž wall to your product inside, allowing for very effective regulace teploty.

There are a few main types of jackets for these stainless steel jacketed tanky:

- Conventional Jacket: A full outer shell covering most of the nádrž. Simple and effective.

- Dimple Jacket: This uses a thinner outer sheet spot-welded to the inner nádrž, creating little bumps or “dimples.” This forces the heating/cooling fluid to swirl around, making heat transfer more efficient. You see dimple jackets a lot on brewery fermenters and brite tanky. It requires less pressure to operate effectively.

- Half-Pipe Coil Jacket: Coiled pipes are welded directly onto the outside of the nádrž. This design is very strong and can handle high pressures, often used for high temperatures or special heating fluids.

So, if you need to cook, pasteurize, ferment at a specific temperature, cool down quickly, or even just insulate the contents of your nádrž to keep the temperature steady, you absolutely need a jacketed tank. For breweries, controlling temperatures in the mash konvice, fermenters, and conditioning tanky is fundamental, making the bunda a non-negotiable feature on many tanky. We help you figure out if you need a bunda and which type is best for your míchací nádrž based on your specific needs. A stainless steel heated nádrž with a bunda offers incredible process control.

What Capacity Do You Need? Exploring Gallon Sizes (30 Gallon, 100 Gallon, and More)

Choosing the right size, or gallon capacity, for your míchací nádrž is super important. Get it wrong, and you could be inefficient, waste space, or spend too much. The needs vary wildly! A small startup brewpub might be perfectly happy with 30 gallon fermenters, or perhaps a few 50-gallon tanky. A growing craft brewery might need several tanky measured in hundreds or even thousands of gallons. A food processing place might use a 100 gallon míchací nádrž for making sauces, but then have much larger tanky (thousands of gallons) for storing bulk ingredients. It’s not just about today; you need to think about tomorrow too. Will you grow?

Here’s a rough idea of how different gallon sizes are used:

| Tank Size (Gallons) | Typical Applications | Úvahy |

|---|---|---|

| 10-30 Gallon | Pilot batches, small startups (nano-breweries), R&D, additives | Fits small spaces, easier for manual tasks |

| 50-100 Gallon | Small brewpubs, moderate batch sizes, test kitchens | Good balance: useful batch size, manageable footprint |

| 200-500 Gallon | Growing craft breweries, mid-size food processing plants | Needs more floor space, often benefits from CIP |

| 1000+ Gallon | Regional/large breweries, large-scale food/nápoje plants | Major space/utility needs, bigger investment |

As manufacturers supplying mixing tanks USA-wide and internationally, we offer a huge řada velikostí. When helping clients choose, we ask them to think about:

- Your Batch Size: How much product do you make at once? Your nádrž should hold that amount plus some extra room at the top (headspace), usually 15-25% extra gallon kapacitu.

- How Often You Produce: Making small batches frequently might mean smaller tanky work. Making huge batches less often needs bigger gallon capacities.

- Your Other Equipment: Does the míchací nádrž need to match the size of your konvice or filling line? The whole system should flow smoothly. A Systém na vaření piva 1000L needs appropriately sized downstream tanky.

- Your Space: Seriously, measure your facility! A big gallon nádrž needs floor space a height clearance.

- Future Plans: Thinking of expanding? Getting slightly larger tanky now might save you money and hassle later. A 30 gallon nádrž serves a very different need than a massive nádrž.

Getting the gallon size right means your production runs efficiently. You won’t be wasting time with tiny batches in a huge nádrž, or constantly running production because your tanky are too small.

Why is Customization Crucial for Your Specific Mixing Tank Needs?

Sure, you can find standard, off-the-shelf míchací nádrže. But let’s be honest – how often does a “standard” solution fit perfectly? Especially in specialized fields like craft brewing or unique food processing, your process has specific needs. That’s where customization comes in, and why it’s so important. As manufacturers who live and breathe custom stainless steel fabrication, particularly tanky for the brewing and beverage industry, we know that tailoring a nádrž to your specific application makes a world of difference. A custom tank isn’t just a luxury; it optimizes how you work, improves your product quality, and fits seamlessly into your production line. It’s about getting the exact nádrž you need.

What can be customized on a míchací nádrž? Lots!

- Size & Shape: Need a taller, skinnier nádrž to fit a tight spot? Or a wider, shorter one? We can adjust dimensions.

- Ports, Ports, Ports: Where do you need connections? We can place the inlet, outlet, sample valves, sensor connections (like thermowells for temperature probes), and manways exactly where they make sense for your workflow and process inside the nádrž. We commonly use sanitární Tri-Clamp ferrules for these ports.

- Bottom Shape: Need every last drop out? A cone bottom with a specific slope is great for that, especially for harvesting yeast in brewing or settling solids. Other options like dished or flat-sloped bottoms are available for different nádrž uses. A kónické bottom is very popular.

- Agitator Setup: Got a specific mixer in mind? We design the nádrž to support it properly, including motor mounts and internal baffles if needed.

- Jacket Zones: Need different temperature zones in one nádrž? We can create multiple bunda sections for finer regulace teploty.

- Surface Finish: How smooth does the inside need to be? We offer different levels of polished finish for the interior and exterior, critical for sanitární needs or just for looks. A #4 brushed exterior and a 2B or polished interior are common for tanky.

- Extras: Need a ladder or platform? Sight glasses to see inside? Spray balls for automated cleaning (CIP)? A special lid, like a hinged lid? Want the nádrž insulated (insulate)? We can add all sorts of accessories.

Working with a manufacturer like us, who specializes in custom stainless steel fabrication, means your míchací nádrž becomes a purpose-built tool, not just a generic container. This tailored konfigurace helps you make the best product possible, efficiently and safely. This level of detail for your nádrž je klíčová.

Ensuring Sanitary Design: What Features Matter in Food and Beverage Tanks?

When you’re making something people will eat or drink, keeping things clean isn’t optional – it’s everything. In the food and beverage industry, including brewing, sanitární design for equipment like míchací nádrže is critical for safety and quality. A nádrž used for consumables must be designed to stop bacteria from growing and be super easy to clean and sanitize effectively. As builders of tanks for food a nápoje applications, including countless brewing tanky, we focus heavily on sanitární design features.

What makes a míchací nádrž truly sanitární?

- The Right Material: We use food-grade nerezová ocel, usually 304 nerezová ocel. For products that are extra salty or acidic, we often recommend 316l stainless steel because it has even better odolnost proti korozi. 316L is a top choice for demanding sanitární tanky.

- Smooth Inside: All the surfaces inside the nádrž, especially the welds where pieces of metal join, must be ground completely smooth and often polished. Think mirror-smooth! This eliminates tiny cracks or pits where germs could hide. A high-quality polished finish je klíčová.

- Rounded Corners: Sharp corners inside a nádrž are hard to clean. We design internal corners with gentle curves (radii) so cleaning solutions and brushes can reach everywhere.

- Drains Properly: The bottom of the nádrž needs to slope towards the outlet port so everything drains out – no puddles left behind after emptying or cleaning. Cone bottom designs are excellent for this.

- Clean Connections: All the connection points (inlet, outlet, sensor ports) use special sanitární fittings, like Tri-Clamp connections. These are designed to be taken apart easily for cleaning and inspection, leaving no hidden areas in the nádrž systém.

- Perfect Welds: Welds need to be strong and smooth, without any gaps or holes. We often treat the welds chemically (passivation) to restore the steel’s full odolnost proti korozi around the weld area on the nádrž.

- Ready for CIP: Many facilities use Clean-In-Place (CIP) systems. We design the nádrž so CIP spray balls can be installed to spray cleaning solutions effectively over all internal surfaces.

Investing in a properly designed sanitary mixing tank using 304 nebo nerezová ocel 316L is an investment in your product’s safety, your customers’ health, and your brand’s reputation. It makes cleaning faster and more reliable, significantly reducing contamination risks in your nádrž. This is a core part of high-quality stainless steel mixing equipment.

Beyond the Tank: The Importance of Technical Support and Service?

Buying a big piece of equipment like a stainless steel mixing tank is just the first step. What happens after it arrives? Reliable technická podpora and service make a huge difference. Imagine running into an issue during a critical production run – you need help, fast! As leading manufacturers with customers worldwide, we believe strong support is just as important as the nádrž itself. It’s about partnership, not just a sale.

Why does ongoing support matter so much for your nádrž?

- Setup Help: Getting a new nádrž, especially a complex custom tank or one with an integrated mixer and controls, installed correctly is crucial. We can offer guidance or assistance with installation and commissioning to make sure everything works right from day one.

- Problem Solving: Things happen. If your agitator stops, or you suspect an issue with the bunda, quick troubleshooting support minimizes downtime and lost production. Having experts familiar with your specific nádrž spec is invaluable.

- Maintenance Tips: We want your nádrž to last a long time! We provide advice on preventative maintenance to keep your stainless steel mixing tank performing at its best for years.

- Spare Parts Access: Need a new gasket, seal, valve, or part for your mixer? Knowing you can easily get the right parts for your nádrž keeps things running smoothly.

- Process Advice: Sometimes, you might wonder how to best use your nádrž for a new recipe or specific food product. Our expertise can help you optimize your process, perhaps advising on mixing speeds or regulace teploty profiles.

Choosing a manufacturer who stands behind their tanky with solid technická podpora gives you confidence. It’s peace of mind knowing help is available if you need it, protecting your investment. This is especially true for Startup Craft Brewery Owners learning new equipment or experienced pros pushing production limits. Good support ensures the overall reliability of your míchací nádrž system. Explore our range of Fermentační nádrž z nerezové oceli a Bright Tanks, all backed by our commitment to service.

Are Used Stainless Steel Mixing Tanks a Viable Option?

Everyone loves saving money, so the idea of buying a used stainless steel mixing tank can be tempting. You might find listings under “used industrial equipment” or see an inventory of used tanky online. While it může sometimes work out, especially for non-critical industrial applications, buying used carries significant risks, particularly if you need the nádrž pro sanitární purposes like potraviny a nápoje nebo pharmaceuticals. Careful consideration is needed before purchasing any used stainless steel mixing tanks.

What are the potential downsides of buying a used nádrž?

- Hidden History: You often don’t know what the nádrž was used for previously. Aggressive chemicals? Allergens? Residues could remain, or the steel itself might be compromised. Verifying the past use of a nádrž is tough.

- Wear and Tear: Older tanky can have invisible problems like metal fatigue, tiny cracks, or hidden corrosion (pitting). These could lead to leaks, failures, or contamination down the road. The durability might be compromised.

- Sanitation Issues: Scratches, dents, or bad repairs on the inside surface of the nádrž can create tiny hiding spots for bacteria, making the nádrž impossible to truly sanitize. Assessing the internal sanitární condition is vital but difficult.

- Wrong Fit: A used nádrž was built for someone else’s needs. It’s unlikely to have the perfect gallon size, port locations, bunda type, or agitator mount for your process. Modifying a used nádrž can be expensive and tricky.

- No Backup: Použité mixing tanks for sale almost always come “as is,” meaning no warranty and no manufacturer technická podpora if something goes wrong with the nádrž.

- Old Tech: Na stránkách nádrž design might be outdated and not meet current sanitární standards or efficiency expectations.

So, while a used nádrž might be okay for simple mixing and storage of non-food materials, the risks for brewing, food processing, or pharma are usually too high. Investing in a new, vysoce kvalitní, potentially custom tank from a reputable manufacturer like us ensures you get a nádrž that meets standards, is safe, built for durability, comes with a warranty, and includes access to support. Checking the spec carefully is crucial if considering used industrial mixing tanks.

How Do We, as Brewing Equipment Specialists, Ensure Your Mixing Tank Success?

Here’s the deal: we’re not just churning out metal tanky. We are a Výrobní závod pivovarského zařízení passionate about helping our clients succeed. Whether you’re a Startup Craft Brewery Owner filled with dreams, an Experienced Brewmaster perfecting complex brews in a Pivovarské zařízení 1500L 3 Vessel setup, a growing Brewpub Chain needing consistent quality, a creative Winery or Cider Producer, or a Beverage Entrepreneur exploring Nádrž na fermentaci kombuchy options – we aim to be your partner. Our deep knowledge of the entire brewing process heavily influences how we design and build every stainless steel mixing tank.

Here’s how we ensure your míchací nádrž is a success story:

- Top-Notch Materials: We start with certified 304 nerezová ocel a 316l stainless steel. No cutting corners. This guarantees the durability, odolnost proti korozia sanitární qualities essential for any nápoje or food nádrž. We deliver high-quality stainless steel mixing tanky.

- Made For You (Customization): We excel at custom stainless steel work. Need a specific gallon size to fit your batch? Unique port locations? A special agitator? A tricky bunda design for precise regulace teploty? We build your custom tank pro vaše specific needs.

- Hygiene First (Sanitary Design): Every brewing and food processing nádrž we make follows strict sanitární guidelines. Smooth welds, proper polished finish, easy draining – everything designed to keep your product pure and cleaning simple.

- Seeing the Big Picture (Integrated Solutions): We know your míchací nádrž doesn’t exist in isolation. We design tanks and mixer packages and consider how they fit with your entire production line, from brewhouse to cellar, ensuring everything works together seamlessly. Our automatický varný systém designs consider every nádrž.

- Support You Can Count On: From the first chat about your nádrž needs, through design, installation, and for years after, our team provides expert technická podpora. We’re here to help you get the most from your nádrž investment. We proudly offer mixing tanks USA designed and supported, often made in the USA, meeting rigorous standards.

Our mission is simple: provide high-quality, customizable brewing equipment, focusing on the essential stainless steel mixing and storage tanks, that empower you to make amazing products. We want to build the perfect míchací nádrž solution that helps your business thrive. Your success is our success. Let’s discuss the ideal nádrž pro vás.

Často kladené otázky (FAQ)

-

What’s the difference between 304 and 316L stainless steel for a mixing tank?

304 nerezová ocel is the most common food-grade nerezová ocel pro tanky, offering great general odolnost proti korozi a durability. nerezová ocel 316L includes molybdenum and has less carbon, giving it superior odolnost proti korozi, especially against salts (chlorides) and certain acids. 316L is often chosen for tanky handling products with higher salt, more acidic ingredients (like some sauces or pickles), or in pharmaceutical applications needing maximum purity. The ‘L’ means low carbon, which is better for welding the nádrž structure. -

How often should I clean my stainless steel mixing tank?

For sanitární uses like potraviny a nápoje or pharma, the míchací nádrž must be cleaned thoroughly after every single batch. This prevents any residue buildup or bacteria growth inside the nádrž. The exact cleaning steps (time, temperature, chemicals for CIP) depend on what you’re mixing and industry rules. Consistent cleaning is key for keeping the nádrž sanitární. -

Can I add a jacket to an existing single-wall tank?

While it might seem possible, adding a bunda to an existing single-wall nádrž is usually very difficult, expensive, and risky. It involves complex welding on the nádrž which can warp the metal or compromise its structure or sanitární state. It’s almost always better and more reliable to buy a new nádrž specifically built as a jacketed tank if you need regulace teploty. -

What information do I need to provide to get a quote for a custom mixing tank?

To give you the best quote for a custom tank, we need details! Tell us the gallon size you need, what product(s) you’ll be mixing in the nádrž (this helps with material choice and agitator design), if you need heating or cooling (so we can design the bunda), which nerezová ocel grade you prefer (304 nebo 316L), where you want the ports and manway on the nádrž, the internal/external finish (polished finish?), any size limits for your space, and if you need special certifications like ASME. The more info about your specific application for the míchací nádrž, the better! -

How long does a high-quality stainless steel mixing tank typically last?

A well-made high-quality stainless steel mixing tank (SS 304 nebo 316L) can easily last 20, 30, or even more years with proper care. Stainless steel’s natural durability a odolnost proti korozi give these tanky a very long life. How long vaše nádrž lasts depends on what you mix in it, how often you use it, your cleaning routine, and regular maintenance. Buying a good nádrž is a solid long-term investment. -

What type of agitator is best for brewing?

The “best” agitator for a brewing nádrž depends on which nádrž you mean! Mash/lauter tuns often use slow-moving rakes or simple paddles. Brew kettles might have an agitator to prevent sticking and help boil dynamics/hop usage. Whirlpool tanky usually rely on a tangential inlet port to create the spin, but sometimes use a specific mixer. Fermenters typically don’t need constant agitace, but some brewers use gentle mixing for specific yeast handling. We help brewers choose the right agitator for each specific nádrž in their 500L systém malých pivovarů or larger setup.

Key Takeaways:

- Nerezová ocel (304/316L) is the top choice for míchací nádrže due to durability, odolnost proti korozi, and being sanitární.

- Nádrž designs are adapted for different industries (brewing, food, pharma) and specific mixing and storage tank applications.

- The correct agitator/mixer type is vital for effective mixing in the nádrž, depending on the liquid and process goal.

- Plášťové tanky provide essential regulace teploty (heating or cooling) for many processes via the bunda.

- Vyberte si nádrž gallon capacity (30 gallon, 100 gallon, etc.) based on batch size, space, and future plans.

- Přizpůsobení lets you get the perfect custom tank konfigurace (ports, bottom, bunda) for your needs.

- Sanitární design (polished finish, smooth welds) is critical for tanks for food, nápoje, and pharma.

- Look for manufacturers offering strong technická podpora beyond the initial nádrž purchase.

- New, vysoce kvalitní tanky are generally safer and more reliable than used stainless steel mixing tanks for critical applications. Check out our MÍCHACÍ NÁDOBY page for options.

- As Brewing Equipment Manufacturers, we provide high-quality, customizable stainless steel mixing tanks with expert support.

Ready to upgrade your process with a stainless steel mixing tank designed for excellence? Contact us today to discuss your unique requirements. Let our team design the ideal mixing and storage tank solution for your facility. Let’s build better beverages together, starting with the perfect nádrž. Žádost o cenovou nabídku now!