In the brewing process of alcoholic beverages, the fermentation stage produces a by-product that is often overlooked: heat. It must be noted that the heat generated by normal beer fermentation activities can raise the process temperature by 10-15℃. Under ideal circumstances, the brewing process should be strictly adjusted within a relatively small temperature range to achieve the best results. Failure to take appropriate measures to regulate the heat generated during beer brewing may result in unsatisfactory products. This is also a costly mistake made by many new brewers. Next, the engineers of Micet Craft will introduce you to how to control the fermentation temperature.

Why should we control the fermentation temperature?

Fermentation temperature control may be the only factor that makes the most progress in brewing beer. In general, the typical malt yeast performs best in the 66-72°F range. This is the best place to ensure that your brewer’s yeast does not produce too much unpleasant odor. Yeast will thrive in warm temperatures and will reproduce faster, but in the process will produce more esters. We can avoid this situation by controlling the fermentation temperature.

Fusel: It is usually considered a hot alcoholic taste, that almost tastes boozy or vodka-like. This taste can be removed in the subsequent conditioning process.

Lipids: usually considered fruity, banana, pear, or nail polish remover flavor. Although certain lipids are desirable in certain styles, they should not be present in other beer styles. The taste of lipids can also fade during the conditioning process, but if the content is too much, it may never improve over time.

Acetaldehyde: Usually considered to be the taste of green apple, raw pumpkin, or pumpkin. Acetaldehyde is a natural by-product of the fermentation process, but if the temperature is not controlled, it will appear in excess, which will affect the flavor of the beer.

The peculiar smell mentioned above is a natural by-product of the fermentation process, which will appear in every fermentation. They just cannot be detected under ideal fermentation conditions.

The temperature range required for different styles of beer

The ideal beer fermentation temperature depends on the beer style that the brewer is trying to produce. For example, compared to ale, some Lager beers must have a lower temperature to properly ferment. In a broad sense, a satisfactory beer brewing temperature is between 40-70℃.

Lager fermentation temperature: The beer fermentation temperature of 45-55°F is the best fermentation temperature for brewing high-quality Lager beer.

Ales fermentation temperature: The ideal fermentation temperature for malt wine is 68-72℃.

IPA fermentation temperature: The temperature of about 60℃ can ferment IPA satisfactorily.

Dark beer fermentation temperature: The average temperature conditions for brewing high-quality dark beer vary between 60-67℃.

Pilsner Fermentation Temperature: The Fermentation Temperature Chart categorizes the best fermentation temperature for Pilsner beer as 50-55℃.

Bock Fermentation Temperature: To ferment great bock, the temperature should be regulated between 50 – 52℃. This only slightly differs from the optimal temperature needed to create a great pilsner.

What happens if the fermentation temperature is too high?

The biggest problem that occurs when the fermentation temperature is too high is the peculiar smell of lipids and fusel alcohols produced by the yeast. Sometimes these peculiar smells can be “excessive” because they are not suitable for this beer style.

Your yeast will undergo a relatively strong metabolic reaction, eating everything in front of you, but it will run out of nutrients before eating the sugar. This situation usually leads to incomplete fermentation.

Poor fermentation temperature control usually leads to too high a fermentation temperature, which makes the yeast too sensitive to alcohol toxicity. This means that the yeast will die from alcohol before it reaches tolerance.

Yeast died at the beginning due to heat stress, and only the remaining yeast left behind could do all the work. This situation will reduce the amount of yeast, extend the time required for the fermentation process, and may even make the beer taste bad.

Because yeast generates a lot of heat during the metabolism of the new city, beer starts to ferment at too high a temperature, and the temperature will climb to 80℃, causing the yeast strain to die.

What happens if the fermentation temperature is too low?

Yeast can also have various problems when brewing in colder climates or winter when there is no temperature control. Winter is the traditional brewing time. This is because there are fewer spoilage bacteria and wild bacteria that need to be dealt with in winter. For home brewers, too low a fermentation temperature can cause the following problems:

The fermentation may never start.

Fermentation can be very slow and last for several weeks, eventually getting into trouble.

For ales that require a certain degree of fatty fruit flavor, too low a fermentation temperature can cause the beer to be too clean or too bland for style.

If there is any contamination in your beer, then you will have to start a new brew. The slow start of fermentation caused by poor temperature control may give bacteria a chance to take over and destroy a batch of beer.

When fermentation starts in a colder environment, carbon dioxide may be entrained in the beer. Normally, “degassed” spices will remain in the solution and may affect the final product formed throughout the fermentation process. This is especially true for the “sulfur” aroma and flavor produced during beer fermentation.

How does the home brewer control the fermentation temperature?

Although homebrewers can use simple cooling fans and bathtubs to control the beer fermentation temperature of their self-made equipment, they still need some professional equipment to know what the temperature is. There are several temperature measurement options:

A separate thermometer casing equipped with a temperature probe will provide you with an accurate fermentation temperature. This is the most accurate way to measure and control the temperature of fermented wort.

Or you can rely on the settings on the dial of the temperature controller. What you want to control is the actual temperature of the wort, not the ambient temperature in the refrigerator (which may vary greatly). To this end, the temperature probe is attached to the side of the fermentation tank, and then a bubble film is attached to the top of the probe for insulation.

If it is only used for measurement, then the indoor/outdoor thermometer can check the ambient temperature in the refrigerator very well. You need to place the control unit outside the refrigerator, and the outside temperature (now inside the refrigerator) is the ambient temperature inside the refrigerator.

Your local home brewing supply store may provide a stick thermometer that can be used in the fermentation tank. It is not the most accurate instrument, but it is better than nothing.

A good choice is a liquid-filled thermometer placed in the refrigerator. Compared with the air in the fermentation refrigerator, the liquid reacts much slower to changes in ambient temperature. If you leave the door open for a short period of time, for example when measuring the SG of fermented wort, the liquid thermometer will still measure the same temperature. It also measures fermented beer more accurately than a typical thermometer because it is filled with a liquid-like fermentation tank.

How does the brewery control the fermentation temperature?

Every beer enthusiast knows that the key to brewing high-quality beer depends largely on attention to detail. In addition to selecting the ideal yeast strain, selecting and maintaining the best brewing temperature is crucial to achieving the required beer quality. Although a simple cooling fan and bathtub can be used to control the beer fermentation temperature of self-made equipment, commercial-scale beer fermentation temperature requires special temperature adjustment equipment. The chillers in the brewery are ideal for large-scale brewing production.

Most brewery coolers use an aqueous glycol solution as the coolant (other refrigerants can also be used). These chillers have the following advantages:

- Ethylene glycol helps prevent the circulation pipeline from freezing and clogging the chiller at low temperatures;

- Ethylene glycol has lubricating properties and can be used to keep the cold water meter running smoothly;

- Ethylene glycol can better retain heat and help effectively cool your brewed beer;

How does the brewery chiller work?

The beer cooling system consists of a refrigeration unit, interconnecting pipes, and an automatic temperature regulator. The cooling liquid is cooled in the refrigeration tank before being pumped through the heat exchanger pipes surrounding the fermentation vessel. The heat from the brewing vessel is transferred to the circulating coolant, which is then pumped back to the refrigeration unit for recooling. The overall effect of this heat exchange cycle is to lower the fermentation temperature in the brewery vessel.

How does the brewery chiller adjust the fermentation temperature?

Although the use of frozen glycol as a coolant is very beneficial, if left unregulated, it will over-cool the brewing process. Lower fermentation temperature will completely shut down the fermentation process or lead to incomplete fermentation. To avoid brewing inferior beer, the temperature in the fermentation vessel must be kept constant. This can be achieved by an automatic temperature controller.

A temperature-controlled solenoid valve is connected to the pipe leading to the heat exchanger. Also, a temperature probe is installed in the fermentation tank through a hot well, and the temperature probe can automatically detect thermal changes during the brewing process. The valve mechanism will automatically open or close according to the temperature in the fermenter to restore it to a predetermined value.

No matter which method you choose to control the temperature during the fermentation process, it will cost a lot of time and money. The yeast you use and the environment in which it works can be said to have the greatest impact on beer flavor during the brewing process. There are many special and style-specific yeast strains available for homebrewers and professional brewers. Each yeast strain has an optimal temperature range. Managing the fermentation temperature to make the most of specific yeast strains can take your brewing to another level, or allow you to explore new beer styles that may not have been brewed before.

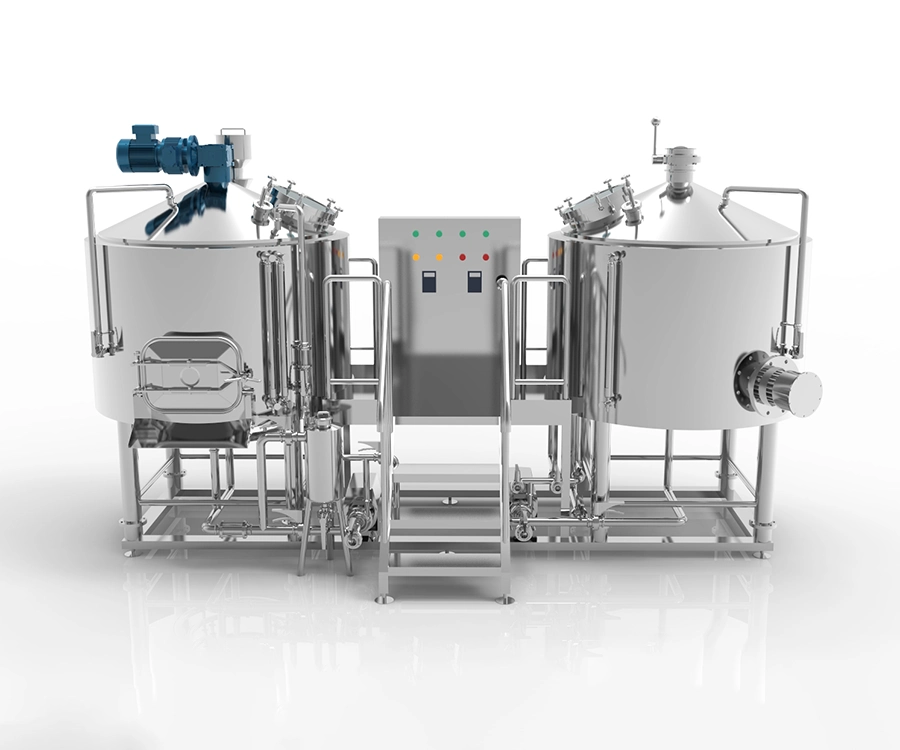

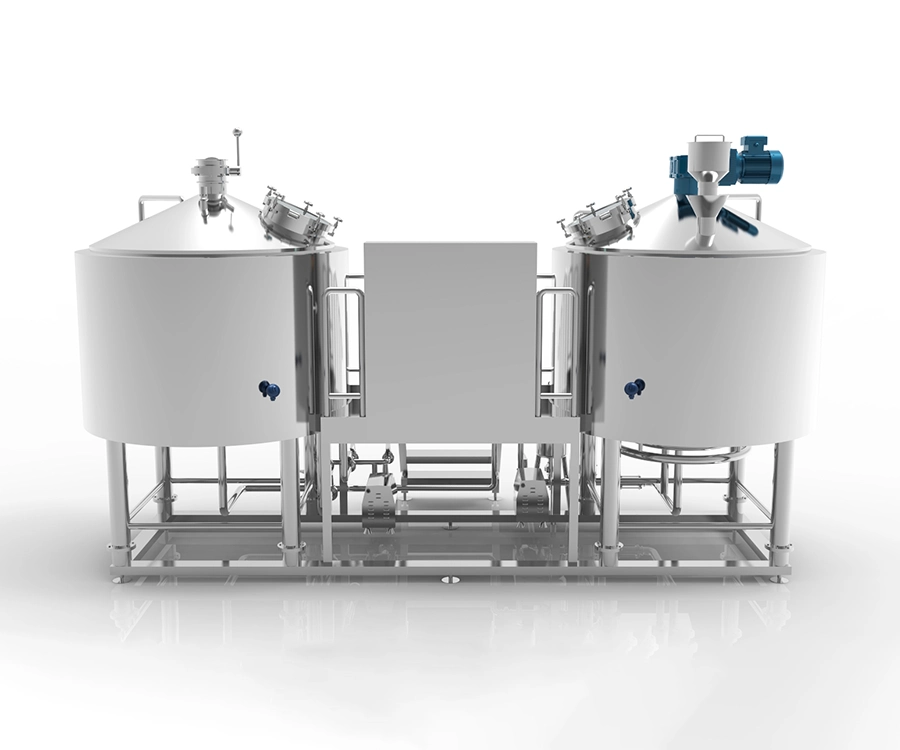

Get a complete turnkey brewery solution

Micet Group is a professional brewery equipment manufacturer. We can provide you with customized brewery design solutions. If you need it, we can also provide you with a complete turnkey brewery solution and price. Of course, if your brewery has an expansion plan, we will also provide you with a list of equipment and related help. Micet Craft is very willing to help your brewery, my friend!