The mash tun is one of the most important components of a beer brewing system, and a key component for demonstrating the technical expertise of equipment manufacturers. In large breweries, the mash tun typically consists of several components, including a mash kettle, lauter tun, filtration tank, boiling tank, and whirlpool tank. Commercial brewing equipment usually comes equipped with two to three mash tuns, with some tanks having multiple functions. According to the usage of mainstream equipment on the market, craft brewing equipment can be roughly divided into several types, including traditional two-vessel mash tuns, classic two-tank three-vessel mash tuns, three-vessel split mash tuns, new three-vessel mash tuns, large three-vessel mash tuns, and large four-vessel mash tuns. These will be described in more detail below.

Traditional two-vessel mash tuns

This type of equipment was one of the earliest used in the beer industry and mainly consists of a mash/boiling kettle and a filtration tank. The mash/boiling kettle can also function as a whirlpool tank, or the mash/filtration and boiling/whirlpool functions can be combined.

The main advantages of this type of equipment include:

- Simple equipment and relatively low investment costs.

- Simple pipelines that are easy to operate.

- Low height of the equipment, with no strict height requirements for the site.

However, the main disadvantages of this type of equipment include:

- When filtering the wort, only the pumping method can be used (i.e., the wort is pumped out of the filtration tank and into the mash/boiling kettle), which results in slow filtration speeds. High technical expertise is required for the brewer to avoid mistakes that can lead to compacted grain beds, difficult filtration, or even deformation of the screen plate, which can affect subsequent use.

- These types of equipment usually have agitators inside the mash/boiling kettle, but due to the whirlpool function of the mash/boiling kettle, the agitator may affect the whirlpool effect.

- The spent grain water can only be prepared in advance and stored in large tubs, water buckets, or fermentation tanks (not recommended to store in fermentation tanks because improper operation may cause vacuum formation or affect the operation of the ice water system). The operation is cumbersome, and heat loss is relatively high.

- Typically, only two batches can be brewed per day at most, requiring the brewer to work overnight.

Classic two-pot and three-vessel mash system

The classic two-pot and three-vessel mash system generally consists of a mash/boiling pot and a filtration/settling tank. The filtration/settling tank is actually composed of two layers, with the upper layer being the filtration tank and the lower layer being the settling tank. However, this type of equipment has been replaced by the new type of three-vessel mash system.

Its main advantages include:

- The equipment has a sleek and tall appearance that conforms to Chinese aesthetics.

- The heating area of the mash/boiling pot is generally large, and it heats up quickly.

- The filtration tank is positioned high, allowing for natural filtration (wort is filtered by gravity), resulting in a high filtration rate and clear wort. Even if there is an operational mistake, there will be no tight mash layer or board deformation.

- The settling tank is designed as a vertical cylindrical tank and is specialized for settling, which results in good separation of hop residue and heat coagulum.

- During wort filtration, the mash/boiling pot can prepare sparge water, and sparging can be carried out at the same time as filtration, shortening the mash time by 30-50 minutes.

- Typically, two batches can be brewed in one day, and if night shifts are considered, three to four batches can be brewed in one day. During the peak season of beer sales, more beer can be brewed in the shortest possible time.

Its main disadvantages are:

- The equipment is generally slightly taller than traditional two-pot mash systems.

- The equipment investment is higher than that of traditional two-pot mash systems.

- Separated three-vessel mash system:

The separated three-vessel mash system has various combination methods, including a mash pot + filtration tank + boiling/settling tank, a mash/filtration tank + boiling pot + settling tank, a mash/filtration tank + boiling/settling tank + hot water tank, and a mash/boiling pot + filtration tank + hot water tank. Although there are many combination methods, the basic principles are similar.

Our Recommendation

Based on the 12 years of sales and market experience, 1000L brewery equipment is the most popular products with its reasonable investment and high return. It is widely used in bar, restaurant and microbrewery business, it combines the advantages of “taproom in front and brewery factory in the back” to create an urban dining and leisure destination that combines local food experience and craft beer products.

Its main advantages include:

- The number of batches that can be brewed per day is equivalent to that of the classic three-vessel mash system.

- The equipment height is relatively low and can adapt to different site restrictions.

- Different mash process parameters can be controlled by changing the combination method.

- It is easy to clean and maintain, reducing maintenance costs and time.

Its main disadvantages are:

- Only the pumping filtration method can be used, resulting in a relatively lower filtration efficiency.

- The equipment takes up a large area and requires sufficient space for layout.

- Special disinfection equipment is required for high-temperature disinfection.

When selecting brewing equipment, comprehensive considerations should be based on your own needs and actual situation, weighing the advantages and disadvantages of the equipment, and choosing the most suitable equipment.

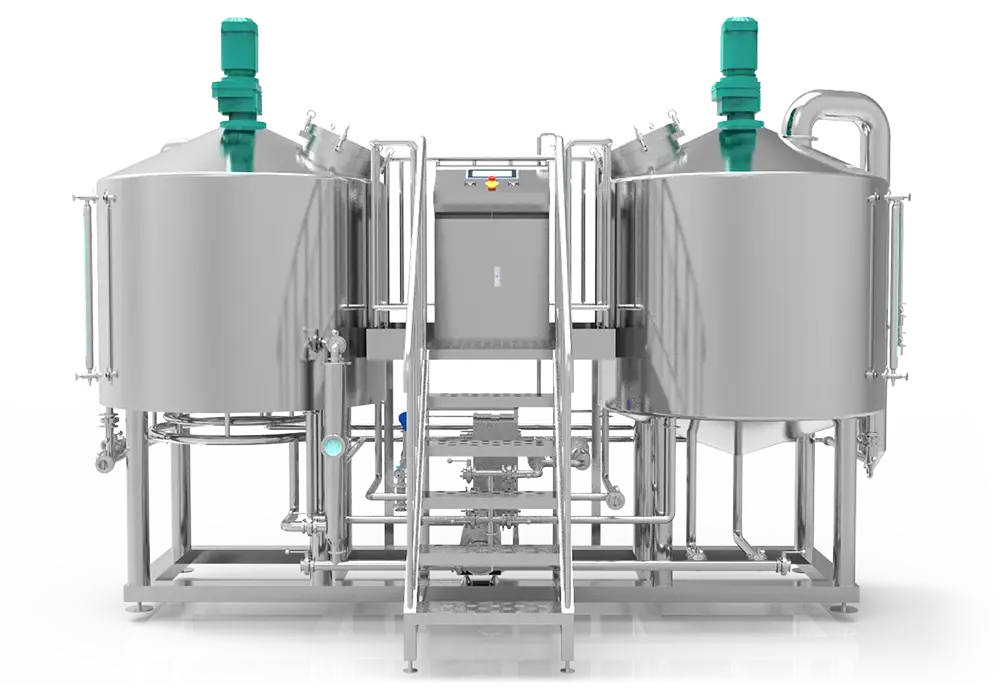

New Type of Double-Vessel Three-Vessel Mash Tun

The new type of double-vessel three-vessel mash tun is the latest modified version of the classic three-vessel mash tun and is one of the widely used brewing equipment by craft beer enthusiasts. The equipment consists of a mash/boiling pot and a filter/centrifuge tank, with the filter tank located above the mash/boiling pot and the centrifuge tank located below the filter tank. In fact, it is a two-layer design.

The advantages of this equipment include:

- The appearance of the equipment has been upgraded, which is in line with the aesthetic standards of the Chinese people. The equipment adopts a horizontal stirring and a cultivator reducer, making the operation more stable. The addition of a jacket design effectively filters out any vibrations that may occur during use, keeping the equipment running smoothly.

- The heating area of the mash/boiling pot is large, and the heating speed is fast and even.

- The filter tank is positioned high, which allows for natural filtration (wort filtered by gravity), resulting in a fast filtration rate and high wort clarity. Even if there are operational errors, issues such as solidified mash layer or warped boards will not occur.

- The centrifuge tank uses a tangential feed design and is specifically designed for separating hop residue and hot coagulum, which has good separation effects.

- While filtering the wort, the mash/boiling pot can also prepare sparge water, which can shorten the mash time by 30 to 50 minutes.

- The equipment has a high production efficiency, with typically two batches brewed in a single day. Considering overtime work, three to four batches can be brewed in a day. During the peak sales season of beer, this equipment can produce more beer in the shortest time.

The disadvantages of this equipment include:

- The equipment is generally slightly taller than traditional two-vessel mash tuns.

- The investment in this equipment is higher than traditional two-vessel mash tuns. The manufacturing cost of this equipment is higher, so the return on investment should be considered when purchasing.

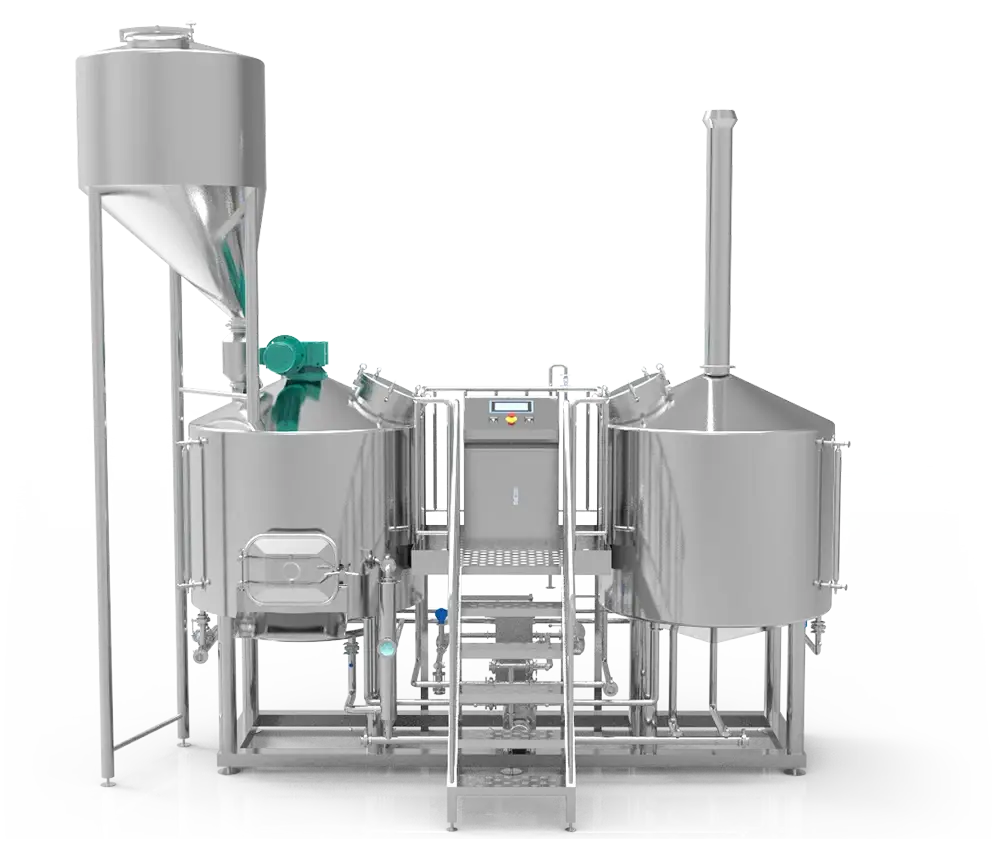

Large-scale Mash/Lauter Tun

Large-scale Mash/Lauter Tun typically has a volume of 1000 liters or more, and is composed of equipment such as mash/lauter tun, boil/whirlpool tun, and hot water tank. In addition, this type of equipment usually comes with auxiliary equipment such as a screw conveyor, wort balance tank, and hop filter tank.

The main advantages of this type of equipment include:

- A powerful assistant for craft breweries. Since mashing, filtering, boiling, and whirlpooling each have separate tanks, plus the equipped hot water tank, it can significantly reduce the time occupying the fermentation tank. Therefore, the total mashing time is generally shortened by 30-60 minutes, and up to 6 batches can be brewed per day. At the same time, the maximum capacity of large fermentation tanks can be increased by up to 5-6 times, thereby improving production efficiency while reducing equipment costs.

- The mash/lauter tun and boil/whirlpool tun use a new type of heating jacket, which can significantly shorten the mash heating time. At the same time, the boiling intensity of the equipment can reach up to 8-10%, which is conducive to protein denaturation and coagulation, and can reduce the content of off-flavor substances.

- The equipment also uses a screw conveyor, which makes the transport of malt powder easy and simple. It should be noted that, in general, the feeding amount of 1000 liters of wort is more than 200 kilograms, which is equivalent to the weight of four bags of fertilizer.

- The wort balance tank is added to achieve natural filtration of the wort.

The main disadvantages of this equipment include:

This type of equipment is usually factory-scale production equipment, and customers need to face food and drug supervision directly. Therefore, the processing requirements for equipment are relatively high. When choosing this type of equipment, in addition to considering the price, factors such as equipment quality, after-sales service, and manufacturer development should also be considered comprehensively.

In large breweries, mash equipment usually consists of multiple components, while commercial beer equipment typically comes with two to three mash vessels, some of which may have multiple functions. According to the usage of mainstream equipment in the market, craft brewing equipment can be roughly divided into traditional two-vessel mash, classic two-vessel three-tun mash, split mash tun, new type three-vessel mash, large-scale three-vessel mash, and large-scale four-vessel mash. Each type of equipment has its own advantages and disadvantages, such as simple equipment, low investment cost, easy operation, etc., but there are also problems such as slow wort filtration speed, cumbersome operation, and high heat loss. Therefore, choosing equipment that is suitable for one’s own production scale and brewer’s technical level is very important.