Whether you are a small brewery or a large industrial brewery, the brewing pump you use is one of the most important pieces of brewing equipment that determine the success or failure of your product. Once in operation, the pump must be well maintained to maintain peak performance. Pumps can be divided into two basic categories: centrifugal pumps and positive displacement pumps.

What is a beer pump?

The basic purpose of a beer pump is to move beer from a keg or other container to the tap. This is an alternative to using air pressure to move the beer. Instead, the pump uses mechanical force to deliver the beer to the tap. Beer pumps are common in beer line systems and must pressures more than 35 or 40 psi to produce consistent flow.

Which is better, a centrifugal pump or a positive displacement pump?

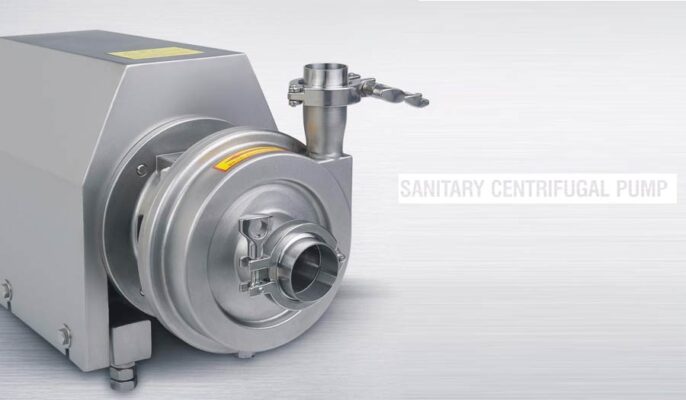

Centrifugal pump

In the brewing industry, hygienic centrifugal pumps are the most used pumps, for conveying low-viscosity fluids with minimal solids concentration at high capacities and low pressures (less than 7 bar). Various types are included: multi-stage, open impeller, liquid ring, and submersible.

Typical applications for which hygienic centrifugal pumps are recommended include:

- Hot wort transfer

- Hot liquid transfer

- CIP pumping and removal

- Canister-to-canister transfer

- Tank cleaning

Positive displacement pump

The most used solvent pumps (PD) in the brewing industry are positive rotary pumps, flexible impeller pumps, progressive cavity pumps, air-operated diaphragm pumps, and twin screw pumps. These are generally suitable for transferring viscous fluids with high solids concentrations at low flow rates at high pressures and where flow accuracy is required.

Typical applications where positive displacement pumps such as peristaltic or diaphragm pumps are recommended include:

- Mash recycling

- Liquid sugar transfer

- Wort juice

- Yeast slurry transfer

- Bottling, drumming, and canning

- Syrup transfer

Why do I need a pump?

The pump is activated whenever you want to move wort into or out of the brewing vessel. For example, if you have a three-vessel setup, a pump can help you transfer your wort from the mash or lauter tun into the boiler. When you’re handling anything but the smallest batches, pumps make the job easy, safe, and clean.

It is also possible to use a pump to recirculate the wort in a single container. You can do this during the mashing process and can help with efficiency. You can also recirculate at the end of the boil to create a vortex, which collects all dregs (and any particulate hops) into the center of the vessel so you can pull clear wort from the rim.

Selection of pump size

Determine traffic

To size and select a centrifugal pump, the flow rate must first be determined. Pipe diameter is an important factor in determining the flow rate of a beer process. Most fluid transfer operations are best performed within the recommended fluid velocity range to achieve non-turbulent flow and cut frictional pressure losses. To prevent turbulent flow in the pipeline, laminar flow must be maintained by keeping the flow velocity below the critical velocity.

Determine the total head

Friction heads are dependent on flow rate, pipe size and length, and liquid viscosity. This is calculated from the values listed in the Water and Viscous Fluids table in the Ingersoll Rand “Cameron Hydraulic Data”. Total head is the pressure the pump must develop to deliver the required flow and is the sum of static head (positive or negative) and friction head.

Pump power

Pump drives are usually electric motors, diesel engines or steam turbines.

It is sized by determining the power required: Pump Power = Flow x Total Head x Liquid Density x Gravitational Acceleration ÷ Pump Efficiency.

How to clean the pump?

- Daily Inspections: Perform daily pump inspections and note any abnormalities, including changes in pump sound, sudden changes in bearing temperature, and seal chamber leaks.

- Leaks: Look for new or excessive leaks, especially oil dripping from gaskets. Check pump casing, seal chamber and piping.

- Noise: If there is some cavitation and bearing noise, make sure the noise is not louder than normal. Lubricate the bearings.

- Heating and Cooling: Watch the temperature of the pump daily to ensure the pump is running at an best temperature. The type of fluid will determine the ideal temperature, which doesn’t fluctuate from day to day.

Frequently Asked Questions

How to reduce foam and agitation when transferring beer to the filling machine?

Centrifugal pumps are an excellent choice for pumping beer. But, due to the transfer of kinetic energy into the liquid at high speeds (1450-2900 rpm), when oxygen enters the beer, the beer tends to froth, which spoils the taste of the beer. Foaming from the beer pump can be reduced by running the beer pump at a slower operating speed and maintaining as constant pressure as possible.

Recommended pumps are:

- Pneumatic diaphragm pump

- Lobe pump

- Flexible impeller pump

How to maintain the temperature of the syrup used in brewing beer?

Twin screw pumps, lobe pumps, and air-operated diaphragm pumps can all be equipped with heating jackets which are fed by hot water or steam to maintain the fluid temperature at the desired temperature to ensure that the viscosity of the syrup is never lower than the set point. The product inside the heating jacket never comes into contact with the syrup, thus maintaining its integrity, quality, and consistency.

What’s up, I check yoսr ƅlog daіly. Your story-telling styⅼe is witty, keep doing what you’re dߋing!