Crafting the Perfect Commercial Brewing Equipment Solution for Your Brewery

Embarking on the journey to start or expand a brewery is an exciting venture. Whether you’re a nano-brewery taking your first steps, a microbrewery aiming to scale up, or a commercial brewery seeking to update your equipment, understanding the intricacies of brewing equipment is crucial. This comprehensive guide will delve into everything you need to know about selecting the right brewing equipment to brew quality beer consistently and efficiently.

Table of Contents

Why Invest in Quality Commercial Brewing Equipment?

Investing in high-quality commercial brewing equipment is essential for producing consistent, quality beer. Quality equipment ensures efficiency, durability, and scalability, allowing your brewery to grow and adapt to market demands. Whether you’re brewing craft beer or large-scale batches, the right equipment lays the foundation for success.

Understanding the Different Types of Breweries

Nano-Brewery

A nano-brewery is a small-scale brewery operation that produces beer in limited quantities, often up to 3 barrels (bbl) per batch. It’s an excellent starting point for enthusiasts entering the brewing industry.

Microbrewery

Microbreweries produce beer in larger quantities than nano-breweries but are still considered small-scale compared to commercial breweries. They focus on craft beers and often have a production limit defined by local regulations.

Commercial Brewery

Commercial breweries operate on a large scale, producing vast quantities of beer for mass distribution. They require robust brewing equipment solutions to handle the high demand and ensure product consistency.

Key Components of Brewing Equipment

Brewhouse

The brewhouse is the heart of any brewery. It typically includes:

- Mash Tun: Where grains are mixed with water to extract sugars.

- Kettle: Used for boiling the wort with hops.

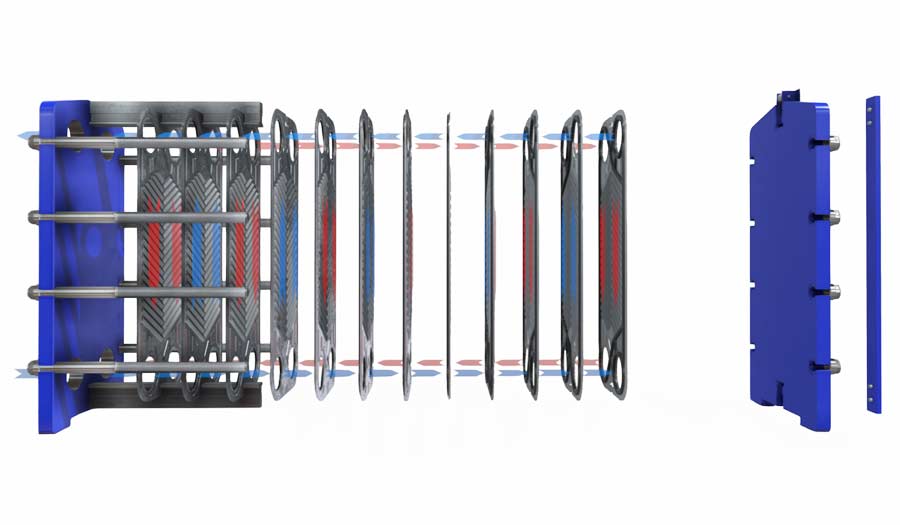

- Heat Exchanger: Cools the wort before fermentation.

Fermenters and Brite Tanks

- Fermenters: Vessels where yeast is added, and fermentation occurs.

- Brite Tanks: Used for conditioning, carbonating, and storing beer.

Pumps and Controls

- Transfer Pumps: Essential for moving liquids between vessels.

- Control Systems: Can be manual or automated to regulate the brewing process.

How to Choose the Right Brewhouse Design

Selecting the ideal brewhouse design depends on your brewery’s size, production goals, and operational preferences.

- Size and Capacity: Consider current needs and future expansion.

- Automation Level: Decide between manual control or automated systems. Automation can increase efficiency but may require a higher initial investment.

- Custom vs. Standard: Custom designs can cater to specific needs, while standard models are more cost-effective.

The Importance of Stainless Steel in Brewing Tanks

Stainless steel is the material of choice for brewing tanks due to its durability, cleanliness, and resistance to corrosion.

- Longevity: Stainless steel tanks have a long lifespan, reducing the need for replacements.

- Sanitation: Easier to clean and sanitize, ensuring the production of high-quality beer.

- Thermal Properties: Efficiently maintain desired temperatures during brewing and fermentation.

Custom vs. Standard Brewing Systems: Which is Right for You?

Custom Brewing Systems

- Advantages:

- Tailored to your specific brewing process.

- Flexible design options.

- Can integrate unique features.

- Considerations:

- Higher cost.

- Longer lead times.

Standard Brewing Systems

- Advantages:

- Cost-effective.

- Quicker delivery and installation.

- Proven designs.

- Considerations:

- Less flexibility.

- May not meet all unique requirements.

Integrating Automation in Your Brewing Process

Automation can revolutionize your brewing operation by enhancing efficiency and consistency.

- Process Control: Automated systems can manage temperatures, timings, and fluid transfers with precision.

- Data Tracking: Monitor brewing parameters and adjust for optimal results.

- Scalability: Easier to scale up production without compromising quality.

The Role of Heat Exchangers in Brewing

A heat exchanger is vital for rapidly cooling wort before fermentation.

- Efficiency: Reduces cooling time, increasing overall brewing efficiency.

- Quality: Minimizes the risk of contamination and off-flavors.

- Types: Plate heat exchangers are commonly used for their effectiveness and compact size.

Maintaining Quality Control in Brewing

Ensuring consistent quality in beer production is paramount.

- Regular Equipment Maintenance: Keep all brewing equipment in optimal condition.

- Sanitation Protocols: Implement strict cleaning procedures.

- Monitoring Systems: Use control systems to monitor variables like temperature and pH levels.

- Employee Training: Educate staff on best practices and equipment handling.

Frequently Asked Questions

What equipment do I need to start a nano-brewery?

To start a nano-brewery, you’ll need a small-scale brewhouse (often up to 3bbl), fermenters, brite tanks, transfer pumps, and basic control systems. Quality brewing equipment tailored to small batches is essential.

Why is stainless steel preferred for brewing equipment?

Stainless steel is durable, easy to clean, and resistant to corrosion, making it ideal for brewing applications. It ensures the production of quality beer by maintaining purity and preventing contamination.

Can I automate my existing brewing system?

Yes, many manufacturers offer retrofitting services to add automation to existing systems. Automation can range from simple temperature controls to fully integrated brewing processes.

How do I choose between a custom and a standard brewing system?

Consider your specific needs, budget, and timeline. Custom systems offer flexibility and tailored solutions, while standard systems are cost-effective and quicker to deploy.

What is the role of a heat exchanger in brewing?

A heat exchanger rapidly cools the wort after boiling, preparing it for fermentation. This step is crucial to prevent bacterial contamination and achieve the desired beer quality.

Conclusion

Selecting the right commercial brewing equipment is a critical step in establishing a successful brewery. From choosing the appropriate brewhouse design to understanding the importance of stainless steel tanks and automation, each decision impacts your operation’s efficiency and the quality of your beer. By investing in quality equipment and staying informed about industry advancements, you position your brewery for long-term success.

Key Takeaways

- Quality Equipment Matters: Invest in durable, efficient brewing equipment to ensure consistent beer production.

- Understand Your Brewery Type: Tailor your equipment choices to the scale and goals of your brewery.

- Stainless Steel is King: Opt for stainless steel tanks for their durability and sanitation benefits.

- Consider Automation: Implementing automation can enhance efficiency and scalability.

- Regular Maintenance is Essential: Keep your equipment in top condition to maintain quality control.

For more insights and to explore our range of brewing solutions, visit our Brewery Equipment Manufacturing Plants page.

Additional Resources

- Optimizing Your Brewery Design: Learn how to design a brewery layout that maximizes efficiency.

- The Importance of Quality Control in Brewing: Explore methods to maintain consistency in your beer production.

- Scaling Up: From Nano to Microbrewery: Strategies for expanding your brewing operation.

Interested in upgrading your brewing equipment? Contact us today to discuss how we can supply the equipment you need to take your brewery to the next level.

“Brewing quality beer is both a science and an art. With the right tools and passion, your craft beer can stand out in the booming brewing industry.”